Want to master SOLIDWORKS without spending a fortune? You can learn SOLIDWORKS for free and become proficient. This guide provides valuable resources to help you gain the necessary skills. Explore options for free SOLIDWORKS training, tutorials, and certification preparation materials to kickstart your journey, all while enhancing your CAD (Computer-Aided Design) expertise and 3D modeling capabilities. For comprehensive learning resources and expert guidance, visit learns.edu.vn today.

1. Unlock SOLIDWORKS Mastery with YouTube’s Model Mania

YouTube is a treasure trove for learning almost anything, and SOLIDWORKS is no exception. While many tutorials are available, the “Model Mania” series stands out as a hidden gem. Let’s delve into what makes Model Mania so special.

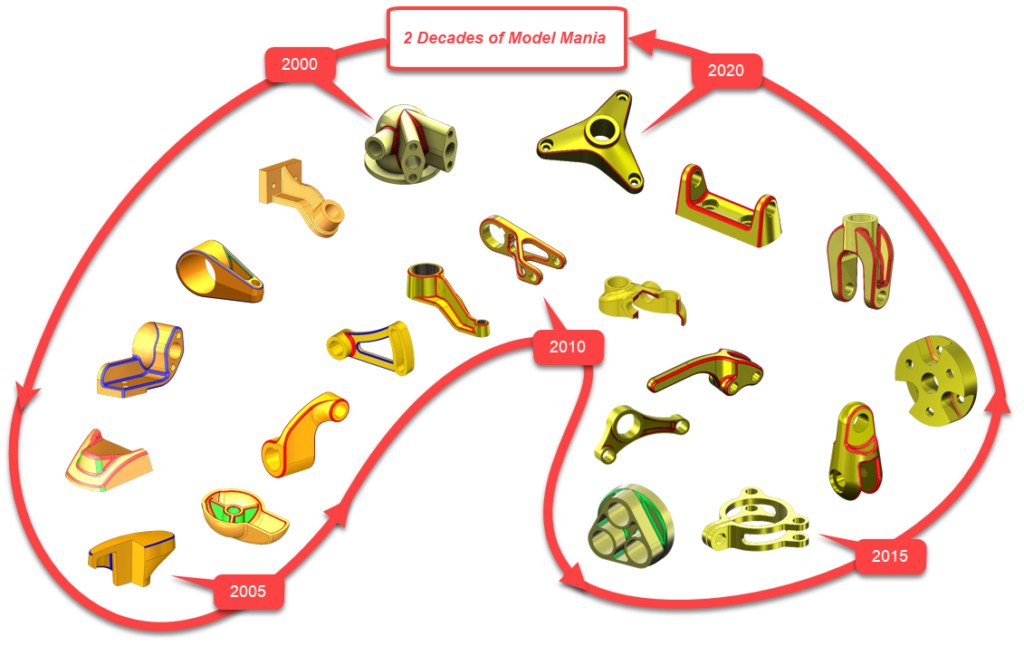

Model Mania is a fast-paced, 20-minute modeling competition held annually at the 3DEXPERIENCE World conference (formerly SOLIDWORKS World). Participants race against the clock to create a 3D model from a 2D print. The challenge escalates in the second phase with unexpected design changes. Top contenders complete the task in approximately 10 minutes, showcasing incredible skill and efficiency.

SOLIDWORKS offers an archive of solution videos from 21 past competitions. You can access the prints here and the complete playlist of solution videos on YouTube.

Model Mania videos are invaluable because they are presented by Mark Schneider from the SOLIDWORKS product introduction team. Mark guides you step-by-step, sharing time-saving techniques along the way. By completing all 21 challenges and following Mark’s guidance, you’ll significantly enhance your SOLIDWORKS modeling abilities.

2. Dive into Thousands of Hours of SOLIDWORKS Content from 3DEXPERIENCE World Recordings

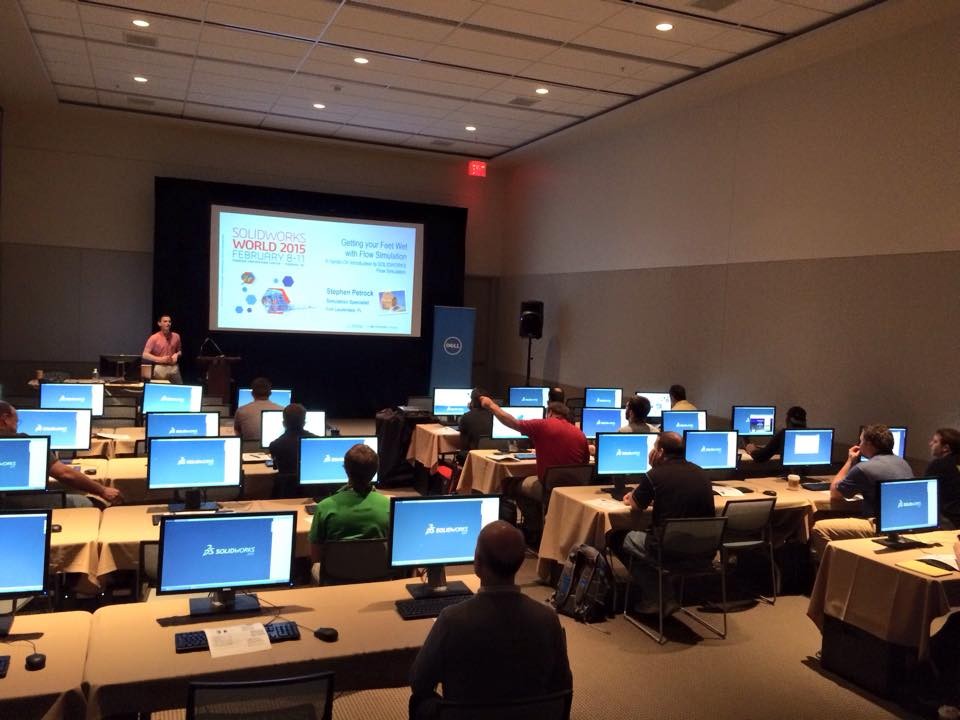

3DEXPERIENCE World is an excellent venue for improving your SOLIDWORKS capabilities and connecting with the community. This event gathers users, industry partners, resellers, and employees for in-depth conversations and knowledge sharing. With around 6,000 attendees, the conference offers countless opportunities for learning. While attending, you might catch a dozen breakout sessions out of the hundreds available.

Fortunately, all sessions are recorded and accessible online with a free username. You can view presentation materials as PowerPoints or PDFs alongside the recordings. Register at 3DExperienceworld.com to gain access.

With nearly 400 presentations at your disposal, you’re sure to find valuable content. Search by topic or presenter, filter by category and product, and learn about everything from drawing templates to surface modeling and large assembly strategies. The 3DEXPERIENCE World recordings are a top resource for SOLIDWORKS learners.

3. Leverage Reseller Webinars for Expert SOLIDWORKS Insights

Your reseller can be a valuable resource for SOLIDWORKS training and content. Application Engineers, product specialists, tech support engineers, and instructors at these companies possess extensive knowledge. Many resellers offer recorded webinars on their websites. Check with your reseller or SOLIDWORKS directly for their webinar libraries.

SOLIDWORKS also hosts the LIVE Design webinar series on its YouTube channel. These webinars, featuring SOLIDWORKS employees, are available on this YouTube playlist. Learning from SOLIDWORKS experts ensures you’re getting accurate and reliable information.

4. Explore Comprehensive Learning Paths with MySOLIDWORKS eLearning

MySOLIDWORKS is a centralized hub for all things SOLIDWORKS, offering structured learning paths rather than just random videos. It’s ideal for guided learning.

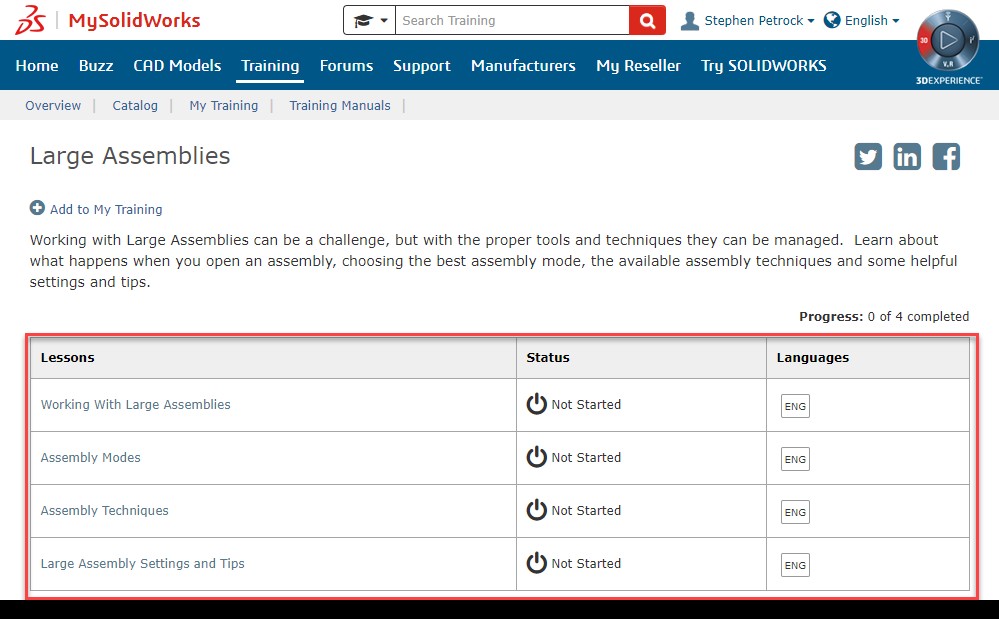

MySOLIDWORKS is free for SOLIDWORKS subscription customers and students with an active Student Engineering Kit (SEK) and Student Edition (SWSE) license. This access includes over 600 SOLIDWORKS training videos and a Certified SOLIDWORKS Associate (CSWA) prep course. The image below shows an example of a learning path for large assembly modeling.

The MySOLIDWORKS Training portal provides example files to follow along with the lessons. With more than 600 training lessons, you can greatly enhance your skills. A subscription to MySOLIDWORKS Professional unlocks SOLIDWORKS eCourses. Contact your reseller for more information on accessing MySOLIDWORKS Professional.

5. SOLIDWORKS Certifications: Validate Your Skills

Certifications are excellent for improving your SOLIDWORKS skills. The preparation required to pass the exams helps solidify your knowledge. SOLIDWORKS Certification Exams demand quick and precise modeling skills.

Preparing for certifications provides a clear learning path and a tangible reward – the certification itself. Many users are pursuing certifications, as seen on platforms like LinkedIn and Reddit. The focused time at home allows for dedicated preparation and exam completion.

How to Obtain SOLIDWORKS Certification at No Cost

It’s possible to take SOLIDWORKS Certification exams without any payment. There are 17 certification exams across three levels: associate, professional, and expert. Here are two ways to take these exams for free:

- Commercial Licenses: Active subscription customers can take up to three exams every six months as part of their subscription.

- Students: Students in a SOLIDWORKS class at an Academic Certification Provider school can take exams for free. Contact your instructor for details.

If you don’t qualify for a free exam, SOLIDWORKS occasionally offers discounts. Check the SOLIDWORKS blog for current promotions.

6. Maximizing Your SOLIDWORKS Learning: A Strategic Approach

Learning SOLIDWORKS effectively involves more than just passively consuming information. It requires a strategic approach that combines various resources and techniques to reinforce your understanding and practical skills. Here’s a comprehensive guide to help you maximize your SOLIDWORKS learning journey.

6.1. Set Clear, Achievable Goals

Start by defining what you want to achieve with SOLIDWORKS. Are you aiming to design specific types of products, pass a certification exam, or enhance your career prospects? Setting clear goals will help you stay focused and motivated.

- Example Goals:

- Master basic part modeling techniques within one month.

- Complete a small personal project, such as designing a custom enclosure for an electronic device, within two months.

- Prepare for and pass the Certified SOLIDWORKS Associate (CSWA) exam within six months.

6.2. Create a Structured Learning Plan

A structured plan ensures you cover all essential topics systematically. Break down your learning into manageable steps, allocating specific time slots for each.

- Sample Weekly Schedule:

| Day | Time | Activity | Resource |

|---|---|---|---|

| Monday | 6:00 PM – 8:00 PM | Basic Part Modeling: Sketching and Extruding | MySOLIDWORKS eLearning |

| Tuesday | 7:00 PM – 8:00 PM | Review and Practice: Recreate a simple part from a reference image | SOLIDWORKS Software |

| Wednesday | 6:00 PM – 8:00 PM | Assembly Basics: Creating and Constraining Assemblies | YouTube Tutorials |

| Thursday | 7:00 PM – 8:00 PM | Review and Practice: Assemble components from previous exercises | SOLIDWORKS Software |

| Friday | 6:00 PM – 8:00 PM | Drawing Creation: Generating 2D Drawings from 3D Models | 3DEXPERIENCE World Recordings |

| Saturday | 10:00 AM – 12:00 PM | Project Work: Work on your personal project | SOLIDWORKS Software, Online Forums |

| Sunday | Rest | Review notes and plan for the next week |

6.3. Utilize a Variety of Resources

Relying on a single resource can limit your understanding. Combining multiple learning methods provides a more comprehensive and engaging experience.

- Recommended Resources:

- MySOLIDWORKS eLearning: Structured courses with practice files.

- YouTube Tutorials: Visual demonstrations and tips from experienced users.

- 3DEXPERIENCE World Recordings: In-depth presentations on advanced topics.

- SOLIDWORKS Help Documentation: Detailed explanations of features and functions.

- Online Forums and Communities: Interaction with other users, asking questions, and sharing knowledge.

6.4. Practice Consistently

Regular practice is crucial for retaining information and developing proficiency. Dedicate time each day or week to work on SOLIDWORKS projects, even if they are small.

- Practice Exercises:

- Recreate parts from engineering drawings.

- Design a simple machine component.

- Assemble existing parts into a functional assembly.

- Participate in online modeling challenges.

6.5. Focus on Fundamentals

Mastering the basics is essential before moving on to more complex topics. Ensure you have a strong understanding of sketching, feature creation, and assembly techniques.

- Key Fundamental Topics:

- Sketching: Lines, circles, arcs, relations, and constraints.

- Feature Creation: Extrude, revolve, sweep, loft, and hole wizard.

- Assembly: Mates, patterns, and configurations.

6.6. Take Advantage of SOLIDWORKS Built-in Tutorials

SOLIDWORKS includes a range of built-in tutorials that cover various topics, from basic modeling to advanced simulation. These tutorials provide step-by-step instructions and example files to help you learn at your own pace.

- Accessing Tutorials:

- Open SOLIDWORKS.

- Go to Help > SOLIDWORKS Tutorials.

- Choose a tutorial topic and follow the instructions.

6.7. Seek Feedback and Collaboration

Engage with the SOLIDWORKS community to get feedback on your designs and learn from others. Participate in online forums, join local user groups, or collaborate with colleagues on projects.

- Ways to Get Feedback:

- Share your designs on online forums and ask for critiques.

- Attend local SOLIDWORKS user group meetings.

- Collaborate with colleagues on projects and exchange ideas.

6.8. Explore Advanced Topics and Specializations

Once you have a solid foundation, explore advanced topics and areas of specialization that interest you. This could include surfacing, weldments, sheet metal, mold design, simulation, or API programming.

- Advanced Topics:

- Surfacing: Creating complex shapes using curves and surfaces.

- Weldments: Designing structures made of welded components.

- Sheet Metal: Designing parts made from thin metal sheets.

- Mold Design: Creating molds for plastic injection molding.

- Simulation: Analyzing the performance of designs under various conditions.

- API Programming: Automating tasks and customizing SOLIDWORKS using programming languages.

6.9. Get Certified

Earning a SOLIDWORKS certification validates your skills and demonstrates your proficiency to potential employers. Prepare for the certification exam by reviewing the exam objectives and practicing with sample questions.

- SOLIDWORKS Certifications:

- Certified SOLIDWORKS Associate (CSWA)

- Certified SOLIDWORKS Professional (CSWP)

- Certified SOLIDWORKS Expert (CSWE)

6.10. Stay Updated

SOLIDWORKS is continuously evolving, with new features and enhancements added in each version. Stay updated by following the SOLIDWORKS blog, attending webinars, and participating in online forums.

- Ways to Stay Updated:

- Read the SOLIDWORKS blog.

- Attend SOLIDWORKS webinars.

- Participate in online forums and communities.

- Follow SOLIDWORKS on social media.

By following these strategies, you can maximize your SOLIDWORKS learning and develop the skills you need to succeed in your career.

7. Essential SOLIDWORKS Terminology for Beginners

Understanding the basic terminology used in SOLIDWORKS is crucial for anyone starting their journey with this powerful CAD software. Here’s a glossary of essential terms to help you navigate SOLIDWORKS more effectively.

7.1. General Terms

- CAD (Computer-Aided Design): The use of computer software to design and document a product’s design process.

- 3D Modeling: Creating a three-dimensional representation of an object using software.

- Part: A single component or element of a design.

- Assembly: A collection of parts connected to form a complete product or mechanism.

- Drawing: A 2D representation of a part or assembly, used for manufacturing and documentation.

- Feature: A geometric shape or operation that adds to or modifies a part, such as an extrude, cut, or fillet.

- Sketch: A 2D profile that forms the basis for many 3D features.

- Mate: A constraint that defines the position and orientation of parts in an assembly.

- Configuration: A variation of a part or assembly with different dimensions, features, or properties.

7.2. Sketching Terms

- Origin: The (0,0,0) point in the SOLIDWORKS coordinate system. It is the starting point for sketches and models.

- Line: A straight line segment defined by two endpoints.

- Circle: A closed curve defined by a center point and a radius.

- Arc: A curved line segment defined by a center point, radius, and two endpoints.

- Spline: A smooth curve defined by a series of control points.

- Relation: A geometric constraint that defines the relationship between sketch entities, such as horizontal, vertical, tangent, or coincident.

- Dimension: A numerical value that specifies the size or position of a sketch entity.

- Fully Defined Sketch: A sketch where all entities are constrained by relations and dimensions, preventing any further changes to its shape or position.

- Under Defined Sketch: A sketch where some entities are not fully constrained, allowing them to be moved or resized.

- Over Defined Sketch: A sketch where there are conflicting or redundant constraints, making it impossible to solve.

7.3. Feature Modeling Terms

- Extrude: A feature created by extending a sketch along a specified direction.

- Cut: A feature created by removing material from a part using a sketch.

- Revolve: A feature created by rotating a sketch around an axis.

- Sweep: A feature created by moving a sketch along a path.

- Loft: A feature created by blending multiple sketches together.

- Fillet: A rounded edge or corner.

- Chamfer: A beveled edge or corner.

- Hole Wizard: A tool for creating standard holes, such as tapped holes, counterbores, and countersinks.

- Pattern: A tool for creating multiple instances of a feature or part.

- Mirror: A tool for creating a reflected copy of a feature or part.

- Shell: A feature that removes material from the interior of a part, leaving a thin wall thickness.

- Rib: A thin, supporting feature that adds strength to a part.

- Draft: A slight angle applied to the faces of a part, used for mold design.

7.4. Assembly Terms

- Mate: A constraint that defines the position and orientation of parts in an assembly.

- Coincident Mate: A mate that aligns two faces, edges, or vertices.

- Concentric Mate: A mate that aligns the center axes of two circular features.

- Parallel Mate: A mate that makes two faces or planes parallel to each other.

- Perpendicular Mate: A mate that makes two faces or planes perpendicular to each other.

- Distance Mate: A mate that specifies the distance between two faces or planes.

- Angle Mate: A mate that specifies the angle between two faces or planes.

- Fixed Component: A component that is fully constrained and cannot be moved.

- Floating Component: A component that is not fully constrained and can be moved.

- Subassembly: An assembly that is used as a component in a larger assembly.

- Bill of Materials (BOM): A list of all the parts and components in an assembly, along with their quantities and descriptions.

7.5. Drawing Terms

- View: A 2D representation of a part or assembly from a specific viewpoint.

- Orthographic View: A view that shows the part or assembly from a direction perpendicular to one of its faces.

- Isometric View: A view that shows the part or assembly from a three-dimensional perspective.

- Section View: A view that shows the internal features of a part or assembly by cutting through it with a plane.

- Detail View: A magnified view of a small area of the part or assembly.

- Dimension: A numerical value that specifies the size or position of a feature in a drawing.

- Annotation: Text or symbols that provide additional information about the part or assembly.

- Tolerance: The allowable variation in a dimension.

- Datum: A reference point, line, or plane used to establish the accuracy of other features in a drawing.

- Surface Finish: The texture of a surface, specified using symbols.

7.6. Simulation Terms

- Finite Element Analysis (FEA): A numerical method for analyzing the behavior of structures under various conditions.

- Mesh: A network of elements used to divide the part or assembly into smaller, more manageable pieces for analysis.

- Stress: The internal force per unit area within a material.

- Strain: The deformation of a material caused by stress.

- Displacement: The distance that a point on the part or assembly moves under load.

- Factor of Safety: The ratio of the material’s strength to the actual stress in the part or assembly.

- Boundary Condition: A constraint that defines how the part or assembly is supported or loaded.

- Load: A force or pressure applied to the part or assembly.

- Material Properties: The physical properties of the material, such as Young’s modulus, Poisson’s ratio, and density.

- Thermal Analysis: A simulation that analyzes the temperature distribution within a part or assembly.

- Fluid Analysis: A simulation that analyzes the flow of fluids around or through a part or assembly.

Understanding these terms will provide a solid foundation as you learn and use SOLIDWORKS for your design and engineering projects.

8. Utilizing SOLIDWORKS for Various Industries: Real-World Applications

SOLIDWORKS is a versatile CAD software used across a multitude of industries due to its robust features and user-friendly interface. Understanding how SOLIDWORKS is applied in different sectors can provide valuable insights into its capabilities and potential applications. Here’s a look at how SOLIDWORKS is utilized in various industries:

8.1. Aerospace Industry

In the aerospace industry, precision and reliability are paramount. SOLIDWORKS is used for designing aircraft components, including structural parts, engine components, and interior fittings.

- Applications:

- Aircraft Design: Creating detailed 3D models of aircraft structures and components.

- Engine Components: Designing and analyzing engine parts such as blades, casings, and fuel systems.

- Interior Design: Designing and modeling cabin interiors, including seating, lighting, and storage solutions.

- Simulation: Performing stress analysis and fluid dynamics simulations to ensure structural integrity and performance.

8.2. Automotive Industry

The automotive industry relies heavily on CAD software for designing vehicles and their components. SOLIDWORKS helps automotive engineers create detailed models of car bodies, chassis, and interior parts.

- Applications:

- Vehicle Design: Designing and modeling car bodies, chassis, and interior components.

- Powertrain Design: Designing engine parts, transmissions, and exhaust systems.

- Manufacturing Tooling: Creating molds and dies for manufacturing plastic and metal parts.

- Ergonomics Analysis: Evaluating the ergonomics of vehicle interiors for driver and passenger comfort.

8.3. Consumer Products Industry

SOLIDWORKS is widely used in the design and development of consumer products, ranging from electronics to household appliances. Its intuitive interface and powerful modeling tools make it ideal for creating innovative and aesthetically pleasing designs.

- Applications:

- Electronics Design: Designing enclosures for electronic devices, such as smartphones, laptops, and wearables.

- Appliance Design: Creating models of household appliances, including refrigerators, washing machines, and ovens.

- Packaging Design: Designing packaging solutions that are both functional and visually appealing.

- Product Visualization: Creating photorealistic renderings and animations for marketing and sales purposes.

8.4. Medical Device Industry

The medical device industry requires high precision and compliance with strict regulatory standards. SOLIDWORKS is used for designing medical devices, surgical instruments, and prosthetics.

- Applications:

- Device Design: Designing medical devices such as implants, surgical instruments, and diagnostic equipment.

- Prosthetics Design: Creating custom prosthetics tailored to individual patient needs.

- Simulation: Performing biomechanical simulations to evaluate the performance and safety of medical devices.

- Manufacturing Tooling: Designing molds and dies for manufacturing medical device components.

8.5. Industrial Equipment Industry

SOLIDWORKS is used to design heavy machinery, manufacturing equipment, and other industrial tools. Its ability to handle large assemblies and complex geometries makes it suitable for designing robust and reliable equipment.

- Applications:

- Machinery Design: Designing industrial machinery such as conveyor systems, robots, and machine tools.

- Equipment Layout: Planning the layout of equipment in manufacturing facilities.

- Simulation: Performing structural analysis and thermal analysis to ensure equipment reliability.

- Documentation: Creating detailed assembly drawings and bills of materials for manufacturing and maintenance.

8.6. Architecture and Construction Industry

While primarily a mechanical CAD software, SOLIDWORKS can be used for certain aspects of architectural and construction design, particularly for detailed modeling of building components and systems.

- Applications:

- MEP Systems Design: Designing mechanical, electrical, and plumbing (MEP) systems for buildings.

- Structural Detailing: Creating detailed models of structural components such as steel beams and concrete columns.

- Prefabrication Design: Designing prefabricated building modules for faster construction.

- Visualization: Creating 3D renderings and animations for architectural presentations.

8.7. Education and Research

SOLIDWORKS is widely used in educational institutions for teaching CAD and engineering principles. It is also used in research for developing new products and technologies.

- Applications:

- CAD Education: Teaching students the fundamentals of CAD and 3D modeling.

- Engineering Research: Developing and testing new product designs.

- Simulation and Analysis: Performing simulations to validate engineering theories.

- Prototyping: Creating prototypes of new products using 3D printing and other manufacturing techniques.

By understanding how SOLIDWORKS is applied in these various industries, you can gain a broader perspective on its capabilities and potential uses in your own field.

9. Advanced SOLIDWORKS Techniques: Elevate Your Design Skills

Once you have a solid understanding of the fundamentals of SOLIDWORKS, it’s time to explore advanced techniques that can help you create more complex and efficient designs. Here are some advanced SOLIDWORKS techniques to elevate your design skills:

9.1. Surfacing

Surfacing is a technique used to create complex, curved shapes that are difficult or impossible to model using traditional solid modeling methods. Surfaces are mathematical representations of the outer skin of a part, and they can be manipulated to create a wide variety of shapes.

-

Applications:

- Designing complex shapes for automotive bodies, aircraft fuselages, and consumer products.

- Creating smooth, continuous surfaces for aesthetic purposes.

- Modeling parts with varying wall thicknesses.

-

Techniques:

- Creating surfaces from sketches, curves, and imported data.

- Using surface editing tools to trim, extend, and knit surfaces together.

- Converting surfaces to solid bodies using the Thicken feature.

9.2. Sheet Metal Design

Sheet metal design is a specialized area of SOLIDWORKS that focuses on creating parts from thin metal sheets. SOLIDWORKS provides tools for creating sheet metal features such as bends, flanges, and hems, as well as for flattening sheet metal parts for manufacturing.

-

Applications:

- Designing enclosures for electronic devices.

- Creating brackets, panels, and other structural components.

- Designing custom sheet metal parts for manufacturing.

-

Techniques:

- Creating base flanges, edge flanges, and miter flanges.

- Adding bends, hems, and other sheet metal features.

- Using the Flatten feature to create a flat pattern for manufacturing.

9.3. Weldments

Weldments are structures made from welded components, such as steel beams, pipes, and plates. SOLIDWORKS provides tools for creating weldment structures, including predefined structural members, corner treatments, and weld beads.

-

Applications:

- Designing frames for machinery and equipment.

- Creating structural supports for buildings and bridges.

- Designing custom weldment structures for manufacturing.

-

Techniques:

- Inserting structural members from the SOLIDWORKS library or custom profiles.

- Using corner treatments to create clean and efficient connections.

- Adding weld beads to simulate the welding process.

9.4. Mold Design

Mold design involves creating molds for plastic injection molding. SOLIDWORKS provides tools for designing mold cavities, cores, and other mold components.

-

Applications:

- Designing molds for plastic parts used in consumer products, automotive components, and medical devices.

- Creating complex mold geometries for intricate parts.

- Simulating the injection molding process to optimize mold design.

-

Techniques:

- Creating parting lines and parting surfaces.

- Designing mold cavities and cores.

- Adding cooling channels and ejector pins.

- Analyzing the mold design using SOLIDWORKS Plastics.

9.5. API Programming

The SOLIDWORKS API (Application Programming Interface) allows you to automate tasks and customize SOLIDWORKS using programming languages such as Visual Basic for Applications (VBA) or C#.

-

Applications:

- Automating repetitive tasks, such as creating drawings or generating reports.

- Customizing the SOLIDWORKS interface to improve productivity.

- Integrating SOLIDWORKS with other software applications.

-

Techniques:

- Using the SOLIDWORKS API to access SOLIDWORKS objects and methods.

- Creating custom macros and add-ins to automate tasks.

- Debugging and testing API code.

9.6. Simulation

SOLIDWORKS Simulation allows you to analyze the performance of your designs under various conditions, such as stress, strain, and temperature.

-

Applications:

- Verifying the structural integrity of parts and assemblies.

- Optimizing designs for performance and efficiency.

- Identifying potential design flaws before manufacturing.

-

Techniques:

- Setting up simulation studies, including defining material properties, loads, and boundary conditions.

- Meshing the model to create a finite element representation.

- Running the simulation and analyzing the results.

- Using the results to optimize the design.

By mastering these advanced SOLIDWORKS techniques, you can take your design skills to the next level and create more complex, efficient, and innovative products.

10. Top Online Communities and Forums for SOLIDWORKS Users

Engaging with the SOLIDWORKS community can significantly enhance your learning experience, provide support, and offer valuable insights. Here are some of the top online communities and forums where you can connect with other SOLIDWORKS users:

10.1. SOLIDWORKS Forums

The official SOLIDWORKS Forums are a great place to start. They are managed by SOLIDWORKS and offer a wealth of information, including discussions, tutorials, and announcements.

-

Features:

- Organized by topic, making it easy to find relevant discussions.

- Moderated by SOLIDWORKS experts and experienced users.

- Includes a knowledge base with articles and FAQs.

-

Benefits:

- Access to official SOLIDWORKS information and support.

- Opportunity to learn from experienced users.

- Ability to ask questions and get help with specific problems.

10.2. SOLIDWORKS Subreddit (r/SolidWorks)

The SOLIDWORKS Subreddit on Reddit is a popular community where users share their designs, ask questions, and discuss SOLIDWORKS topics.

-

Features:

- User-driven content, including images, videos, and discussions.

- Active community with a wide range of experience levels.

- Opportunity to get feedback on your designs.

-

Benefits:

- Access to a diverse range of perspectives and experiences.

- Opportunity to showcase your work and get feedback.

- Ability to stay up-to-date on the latest SOLIDWORKS news and trends.

10.3. CAD Forum

CAD Forum is a general CAD forum that includes a dedicated section for SOLIDWORKS. It’s a great place to ask technical questions and get help with specific problems.

-

Features:

- Organized by CAD software, including SOLIDWORKS.

- Active community of CAD users and experts.

- Includes a library of CAD blocks and symbols.

-

Benefits:

- Access to a broad range of CAD knowledge and expertise.

- Opportunity to get help with technical problems from experienced users.

- Ability to share your knowledge and help others.

10.4. Eng-Tips Forums

Eng-Tips Forums are a professional engineering forum that includes a section for CAD and design. It’s a great place to discuss complex engineering problems and get advice from experienced engineers.

-

Features:

- Focus on professional engineering topics.

- Active community of engineers from various disciplines.

- Opportunity to discuss complex engineering problems and get advice.

-

Benefits:

- Access to a high level of engineering expertise.

- Opportunity to learn about different engineering disciplines.

- Ability to network with other engineers.

10.5. LinkedIn Groups

There are several SOLIDWORKS-related groups on LinkedIn where you can connect with other users, share your work, and discuss industry trends.

-

Features:

- Professional networking platform.

- Opportunity to connect with other SOLIDWORKS users and industry professionals.

- Ability to share your work and participate in discussions.

-

Benefits:

- Opportunity to build your professional network.

- Ability to stay up-to-date on industry trends.

- Opportunity to find job opportunities and career advice.

By participating in these online communities and forums, you can connect with other SOLIDWORKS users, learn from their experiences, and get help with your own projects.

11. Frequently Asked Questions (FAQs) About Learning SOLIDWORKS for Free

Here are some frequently asked questions about learning SOLIDWORKS for free, along with detailed answers to help guide you:

Q1: Is it really possible to learn SOLIDWORKS without paying for expensive courses?

A: Yes, it is absolutely possible to learn SOLIDWORKS for free. There are numerous resources available online, including YouTube tutorials, reseller webinars, the MySOLIDWORKS platform, and free certification options. By leveraging these resources and dedicating time to consistent practice, you can become proficient in SOLIDWORKS without spending a fortune.

Q2: What are the best free resources for learning SOLIDWORKS?

A: Some of the best free resources include:

- YouTube Tutorials: Channels like SOLIDWORKS and individual creators offer a wealth of tutorials covering various topics.

- 3DEXPERIENCE World Recordings: Access recorded sessions from the annual SOLIDWORKS conference.

- Reseller Webinars: Many SOLIDWORKS resellers offer free webinars that cover specific features and techniques.

- MySOLIDWORKS: The MySOLIDWORKS platform offers free training videos and learning paths for SOLIDWORKS subscription customers and students.

- SOLIDWORKS Built-in Tutorials: SOLIDWORKS includes a range of built-in tutorials that cover various topics, from basic modeling to advanced simulation.

Q3: How long does it take to become proficient in SOLIDWORKS?

A: The time it takes to become proficient in SOLIDWORKS varies depending on your learning style, dedication, and goals. However, with consistent practice and the right resources, you can achieve a basic level of proficiency in a few months. Mastering advanced techniques and becoming an expert may take a year or more.

Q4: Do I need any prior experience to learn SOLIDWORKS?

A: No prior experience is required to learn SOLIDWORKS. However, a basic understanding of engineering principles and CAD concepts can be helpful. The free resources mentioned above are designed for beginners and provide step-by-step instructions to guide you through the learning process.

Q5: Can I get SOLIDWORKS certification without paying for the exams?

A: Yes, there are ways to get SOLIDWORKS certification without paying for the exams. If you have an active SOLIDWORKS subscription, you may be eligible for free certification exams. Additionally, students attending schools that are Academic Certification Providers can often take exams for free.

Q6: What are the benefits of getting SOLIDWORKS certified?

A: Getting SOLIDWORKS certified offers several benefits, including:

- Validation of Skills: Certification validates your skills and demonstrates your proficiency to potential employers.

- Career Advancement: Certification can enhance your career prospects and open up new job opportunities.

- Increased Confidence: Achieving certification can boost your confidence in your abilities.

- Industry Recognition: SOLIDWORKS certification is recognized and respected in the industry.

Q7: How can I stay updated on the latest SOLIDWORKS features and updates?

A: To stay updated on the latest SOLIDWORKS features and updates, you can:

- Follow the SOLIDWORKS Blog: The official SOLIDWORKS blog provides information on new features, updates, and industry trends.

- Attend Webinars: SOLIDWORKS and its resellers offer webinars that cover the latest features and techniques.

- Participate in Online Forums: Engaging with the SOLIDWORKS community on online forums can help you stay informed about new developments.

- Follow SOLIDWORKS on Social Media: Follow SOLIDWORKS on social media platforms such as Twitter, Facebook, and LinkedIn to get the latest news and updates.

Q8: What kind of computer do I need to run SOLIDWORKS?

A: To run SOLIDWORKS effectively, you need a computer that meets the following minimum requirements:

- Operating System: Windows 10 64-bit

- Processor: 3.3 GHz or higher

- Memory: 16 GB or more

- Graphics Card: NVIDIA Quadro or AMD FirePro with certified drivers

- Storage: 256 GB SSD or more

Q9: Can I use SOLIDWORKS on a Mac?

A: SOLIDWORKS is primarily designed for Windows operating systems. While it is possible to run SOLIDWORKS on a Mac using virtualization software such as VMware or Parallels, this is not officially supported and may result in performance issues.

Q10: Where can I find example files and practice models to improve my SOLIDWORKS skills?

A: You can find example files and practice models in several places:

- MySOLIDWORKS: The MySOLIDWORKS platform offers example files for many of its training courses.

- SOLIDWORKS Tutorials: The built-in SOLIDWORKS tutorials include example files and step-by-step instructions.

- Online Forums: SOLIDWORKS users often share example