PLC programming is a powerful skill that can unlock numerous career opportunities. Are you wondering how hard it is to learn PLC programming? LEARNS.EDU.VN provides a comprehensive guide to help you assess the challenges and rewards of mastering PLC programming. Discover the learning curve, essential skills, and how LEARNS.EDU.VN can support your educational journey.

1. Understanding PLC Programming: An Overview

1.1. What is PLC Programming?

PLC programming involves creating instructions for Programmable Logic Controllers (PLCs), specialized computers used to automate industrial processes. PLCs monitor inputs (sensors, switches) and control outputs (motors, valves) based on programmed logic. According to a report by ARC Advisory Group, the global PLC market is expected to reach $16.2 billion by 2025, highlighting the growing demand for skilled PLC programmers. Ladder logic, industrial automation, and control systems are key concepts.

1.2. Why Learn PLC Programming?

Learning PLC programming can lead to diverse and high-paying careers in manufacturing, automation, and engineering. The U.S. Bureau of Labor Statistics projects a 7% growth for electrical and electronics engineers, who often work with PLCs, from 2020 to 2030. The benefits include job security, competitive salaries, and opportunities for advancement. Process control, HMI design, and SCADA systems are important skills to develop.

2. Factors Influencing the Difficulty of Learning PLC Programming

2.1. Prior Knowledge and Experience

Your background significantly impacts the learning curve. Those with experience in electrical engineering, computer science, or related fields may find PLC programming easier to grasp. A study by the International Society of Automation (ISA) found that individuals with prior technical experience learn PLC programming concepts 30% faster than those without. Electrical circuits, programming fundamentals, and industrial processes are helpful foundations.

2.2. Learning Resources and Support

Access to quality learning resources is crucial. Structured courses, hands-on training, and mentorship can greatly simplify the learning process. LEARNS.EDU.VN offers a range of courses and resources designed to make PLC programming accessible to learners of all levels. Online tutorials, PLC training, and automation courses are valuable.

2.3. Time Commitment and Dedication

Mastering PLC programming requires a significant time investment. Consistent study and practice are essential for success. According to a survey by Control Engineering magazine, successful PLC programmers dedicate an average of 10-15 hours per week to learning and practicing. Continuous learning, skill development, and hands-on experience are vital.

3. Key Skills Needed for PLC Programming

3.1. Understanding of Electrical Concepts

A solid understanding of electrical concepts is fundamental to PLC programming. This includes knowledge of voltage, current, resistance, and basic circuit design. The IEEE (Institute of Electrical and Electronics Engineers) offers resources and certifications to enhance your electrical knowledge. Circuit diagrams, electrical safety, and troubleshooting skills are essential.

3.2. Proficiency in Programming Languages

While ladder logic is the most common PLC programming language, familiarity with others like Structured Text (ST) and Function Block Diagram (FBD) can be beneficial. IEC 61131-3 standard defines the common PLC programming languages. Learning multiple languages, coding standards, and software development practices can improve your capabilities.

3.3. Knowledge of Industrial Processes

Understanding how PLCs are used in various industrial processes is crucial for effective programming. This includes knowledge of manufacturing, automation, and control systems. The Automation Federation provides valuable insights into industrial automation trends and best practices. Process optimization, system integration, and control engineering principles are important.

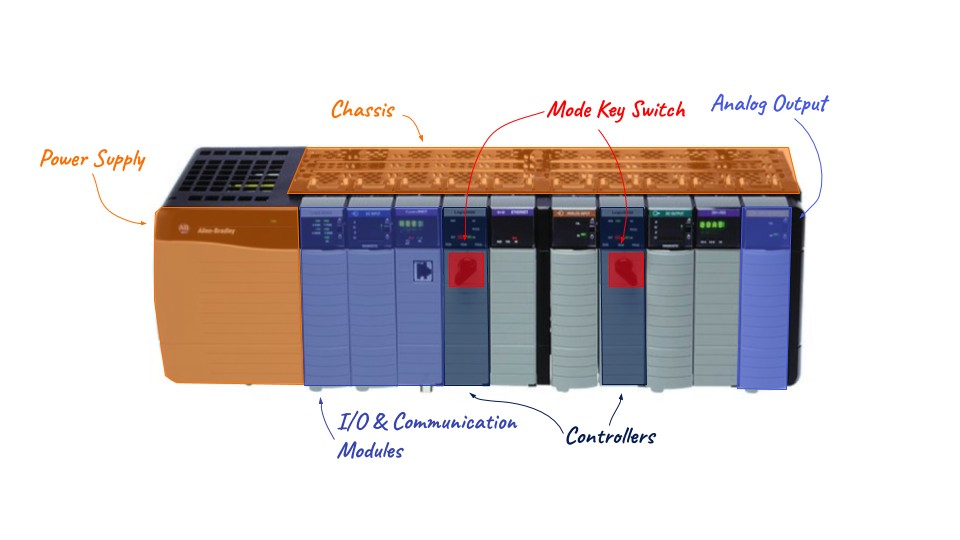

An illustration of Allen Bradley PLC Block diagram highlighting key components for effective automation processes.

4. Step-by-Step Guide to Learning PLC Programming

4.1. Start with the Basics

Begin by understanding the fundamentals of PLCs, their components, and their applications. LEARNS.EDU.VN offers introductory courses that cover these essential concepts. PLC basics, industrial controllers, and automation systems are the foundation.

4.2. Choose a PLC Platform

Select a PLC platform to focus on, such as Allen-Bradley (Rockwell Automation), Siemens, or ABB. Each platform has its own programming software and hardware. According to a report by IHS Markit, Allen-Bradley and Siemens are the leading PLC vendors globally. Allen Bradley training, Siemens PLC programming, and ABB automation solutions are popular choices.

4.3. Learn Ladder Logic

Master ladder logic, the most common PLC programming language. Practice writing simple programs to control basic functions. Online simulators and emulators can be helpful for practicing without physical hardware. Ladder diagrams, programming logic, and PLC instructions are key elements.

4.4. Practice with Real-World Projects

Apply your knowledge by working on real-world projects. This could involve automating a small process or troubleshooting an existing PLC program. Practical experience, hands-on projects, and industrial applications are invaluable.

4.5. Seek Mentorship and Community Support

Connect with experienced PLC programmers and join online communities to ask questions, share knowledge, and learn from others. The PLC forum and the Automation.com community are excellent resources. Networking, peer learning, and expert guidance can accelerate your progress.

5. Common Challenges and How to Overcome Them

5.1. Cost of Hardware and Software

PLC hardware and software can be expensive. Consider using free trial versions or simulators to practice. LEARNS.EDU.VN also offers affordable training options. Virtual PLCs, simulation software, and free PLC resources can help reduce costs.

5.2. Complexity of Industrial Processes

Understanding complex industrial processes can be challenging. Focus on learning one process at a time and seek guidance from experienced professionals. Process analysis, system design, and industrial engineering principles are helpful.

5.3. Troubleshooting and Debugging

Troubleshooting PLC programs requires patience and problem-solving skills. Develop a systematic approach to debugging and use online resources for assistance. Debugging tools, troubleshooting techniques, and PLC diagnostics are essential skills.

6. Resources Available at LEARNS.EDU.VN

6.1. Structured Courses

LEARNS.EDU.VN provides structured courses on PLC programming, covering everything from basic concepts to advanced techniques. Our courses are designed to be accessible and engaging for learners of all levels. Online PLC courses, certification programs, and industrial training are available.

6.2. Hands-On Training

Our hands-on training programs allow you to practice PLC programming with real hardware and software. This practical experience is essential for mastering the skills needed for a successful career. Practical workshops, lab exercises, and simulation projects are included.

6.3. Expert Mentorship

LEARNS.EDU.VN connects you with experienced PLC programmers who can provide guidance, answer questions, and offer valuable insights. Mentorship programs, expert consultations, and career coaching are offered.

7. Comparing PLC Programming to Other Programming Disciplines

7.1. PLC Programming vs. Software Development

While both involve programming, PLC programming focuses on controlling physical devices and processes, whereas software development typically deals with computer applications and systems. Understanding real-time systems, hardware interfaces, and industrial protocols is more critical in PLC programming. Real-time programming, embedded systems, and industrial control theory are important.

7.2. PLC Programming vs. Electrical Engineering

Electrical engineering provides the foundation for understanding the hardware aspects of PLCs, while PLC programming focuses on the software that controls these devices. The two disciplines complement each other, and a strong understanding of both is beneficial. Electrical design, control panel wiring, and automation hardware are relevant skills.

7.3. PLC Programming vs. Automation Engineering

Automation engineering encompasses a broader range of skills, including PLC programming, robotics, and process control. PLC programming is a key component of automation engineering, but automation engineers also need to understand system design and integration. System integration, robotics programming, and process optimization are all areas of expertise.

8. Essential Tools and Software for PLC Programming

8.1. PLC Programming Software

Each PLC platform has its own programming software, such as Rockwell Automation’s Studio 5000, Siemens’ TIA Portal, and ABB’s Automation Builder. Familiarizing yourself with these tools is essential. Programming environments, software interfaces, and configuration tools are vital.

8.2. Simulation and Emulation Software

Simulation and emulation software allows you to test your PLC programs without physical hardware. Popular options include FactoryTalk Emulate and PLCSim. Virtual commissioning, software testing, and offline programming are all facilitated.

8.3. Hardware Components

Having access to PLC hardware, such as CPUs, input/output modules, and communication modules, is crucial for hands-on practice. PLC kits, training modules, and industrial components are useful.

9. Career Paths in PLC Programming

9.1. PLC Programmer

PLC programmers design, develop, and maintain PLC programs for industrial automation systems. They work closely with engineers and technicians to ensure that the programs meet the required specifications. PLC specialist, automation programmer, and controls technician are related roles.

9.2. Automation Engineer

Automation engineers design and implement automated systems for manufacturing and other industries. They use PLCs, robots, and other technologies to improve efficiency and reduce costs. Robotics engineer, process engineer, and system integrator are similar positions.

9.3. Control Systems Engineer

Control systems engineers design and maintain the control systems that regulate industrial processes. They use PLCs, sensors, and other devices to ensure that the processes operate safely and efficiently. Control engineer, instrumentation engineer, and process control specialist are comparable jobs.

An overview of average PLC Programming salaries in the USA, highlighting competitive earnings potential.

10. How to Stay Updated with the Latest Trends in PLC Programming

10.1. Attend Industry Conferences and Webinars

Industry conferences and webinars are excellent opportunities to learn about the latest trends and technologies in PLC programming. The Automation Fair and the ISA Automation Week are popular events. Technical seminars, industry events, and online workshops are valuable.

10.2. Read Industry Publications and Blogs

Stay informed by reading industry publications and blogs, such as Control Engineering, Automation World, and the LEARNS.EDU.VN blog. Industry magazines, online articles, and technical journals are useful resources.

10.3. Participate in Online Communities

Engage with online communities and forums to discuss new technologies, share best practices, and learn from other professionals. Online forums, social media groups, and networking platforms are helpful.

11. Case Studies: Success Stories of PLC Programmers

11.1. Automating a Manufacturing Plant

A PLC programmer automated a manufacturing plant, resulting in a 30% increase in production efficiency and a 20% reduction in costs. This success was achieved through careful system design, efficient PLC programming, and continuous optimization. Productivity gains, cost savings, and process improvements are all possible.

11.2. Developing a Smart Irrigation System

A PLC programmer developed a smart irrigation system that uses sensors to monitor soil moisture and automatically adjust watering schedules. This resulted in a 40% reduction in water usage and improved crop yields. Sustainable solutions, resource management, and environmental benefits are achievable.

11.3. Improving Safety in a Chemical Plant

A PLC programmer improved safety in a chemical plant by implementing a redundant control system that automatically shuts down the plant in the event of a hazardous condition. This reduced the risk of accidents and ensured the safety of the workers. Safety systems, risk mitigation, and hazard prevention are crucial.

12. Tips for Effective PLC Programming

12.1. Write Clear and Concise Code

Write PLC programs that are easy to understand and maintain. Use comments and descriptive variable names to explain the logic. Code readability, maintainability, and documentation practices are important.

12.2. Use Modular Programming Techniques

Break down complex PLC programs into smaller, more manageable modules. This makes the programs easier to debug and modify. Modular design, structured programming, and reusable code are beneficial.

12.3. Test Your Programs Thoroughly

Test your PLC programs thoroughly before deploying them in a production environment. Use simulation and emulation software to identify and fix any errors. Software testing, validation, and quality assurance are essential.

13. Debunking Myths About PLC Programming

13.1. Myth: PLC Programming is Too Difficult for Beginners

Reality: With the right resources and a structured learning approach, anyone can learn PLC programming, regardless of their background. Accessible learning materials, beginner courses, and step-by-step guides can help.

13.2. Myth: PLC Programming is Only for Electrical Engineers

Reality: While electrical engineering knowledge is helpful, individuals from other technical backgrounds can also succeed in PLC programming. Interdisciplinary skills, diverse backgrounds, and transferable knowledge are valuable.

13.3. Myth: PLC Programming is Outdated

Reality: PLC programming is more relevant than ever, with the increasing demand for automation in various industries. Automation trends, technological advancements, and industry growth are driving demand.

14. Future Trends in PLC Programming

14.1. Integration with IoT

PLCs are increasingly being integrated with the Internet of Things (IoT), allowing for remote monitoring and control of industrial processes. IoT integration, remote monitoring, and data analytics are key trends.

14.2. Use of Artificial Intelligence

Artificial intelligence (AI) is being used to optimize PLC programs and improve the efficiency of automated systems. AI optimization, machine learning, and predictive maintenance are emerging technologies.

14.3. Enhanced Cybersecurity

With the increasing connectivity of PLCs, cybersecurity is becoming more important than ever. PLC programmers need to be aware of the latest security threats and best practices. Cybersecurity measures, threat detection, and data protection are essential.

15. Conclusion: Is PLC Programming Right for You?

Learning PLC programming can be challenging, but it is also incredibly rewarding. With dedication, the right resources, and a passion for automation, anyone can master this valuable skill. LEARNS.EDU.VN is here to support you on your journey. Consider your interests, career goals, and willingness to invest time and effort. Job opportunities, career growth, and skill development are all potential benefits.

Ready to embark on your PLC programming journey? Visit learns.edu.vn today to explore our courses and resources. Contact us at 123 Education Way, Learnville, CA 90210, United States or via Whatsapp at +1 555-555-1212. Your future in automation starts here.

16. FAQ: Frequently Asked Questions About PLC Programming

16.1. What is the best PLC platform for beginners?

The best PLC platform for beginners often depends on regional preferences and industry standards. However, Allen-Bradley’s MicroLogix and Siemens’ S7-1200 are frequently recommended due to their user-friendly interfaces and extensive support resources.

16.2. How long does it take to become proficient in PLC programming?

Proficiency in PLC programming can be achieved in 6-12 months with consistent effort and practice. This timeline can vary depending on your background, learning resources, and dedication.

16.3. Do I need a degree to become a PLC programmer?

While a degree in electrical engineering or a related field can be beneficial, it is not always required. Practical skills and certifications are often valued by employers, making hands-on training and relevant experience crucial.

16.4. What are the essential skills for a PLC programmer?

Essential skills include a strong understanding of electrical concepts, proficiency in ladder logic and other PLC programming languages, knowledge of industrial processes, and problem-solving abilities.

16.5. How can I practice PLC programming without expensive hardware?

Simulation software and emulators provide a cost-effective way to practice PLC programming without the need for physical hardware. These tools allow you to create and test programs in a virtual environment.

16.6. What are the common challenges faced by PLC programmers?

Common challenges include troubleshooting complex systems, keeping up with industry advancements, and integrating PLCs with other technologies.

16.7. What is the role of PLC programmers in Industry 4.0?

In Industry 4.0, PLC programmers play a crucial role in integrating PLCs with IoT devices, cloud platforms, and AI-driven systems to create smart, interconnected manufacturing environments.

16.8. How do I prepare for a PLC programming job interview?

To prepare for a PLC programming job interview, review fundamental electrical and programming concepts, practice common programming tasks, and familiarize yourself with different PLC platforms.

16.9. What are the ethical considerations for PLC programmers?

Ethical considerations for PLC programmers include ensuring the safety and reliability of automated systems, protecting sensitive data, and adhering to industry standards.

16.10. What are the latest advancements in PLC technology?

Latest advancements in PLC technology include enhanced cybersecurity features, improved integration with IoT devices, and the use of AI and machine learning to optimize system performance.