Mastering Fusion 360 is a valuable skill in today’s design and manufacturing landscape, and understanding how long to learn Fusion 360 is the first step. At LEARNS.EDU.VN, we’re dedicated to providing clear, actionable guidance to help you become proficient, allowing you to gain practical experience with CAD software. Whether you’re interested in design skills, creative projects, or 3D modeling, we’ll break down the learning process and offer tips to accelerate your progress, ensuring you acquire expertise in computer-aided design.

1. Understanding Fusion 360 and Its Applications

Fusion 360 is more than just a CAD (Computer-Aided Design) software; it’s a comprehensive cloud-based platform that integrates CAD, CAM (Computer-Aided Manufacturing), and CAE (Computer-Aided Engineering) tools. This integration makes it a versatile tool for various industries, from product design to mechanical engineering.

1.1. What is Fusion 360?

Fusion 360 is a 3D CAD, CAM, and CAE tool that connects your entire product development process in a single cloud-based platform. It’s used for designing, testing, and fabricating products. According to Autodesk, Fusion 360 allows users to explore multiple design iterations with simulation and generative design tools, ensuring optimal performance and manufacturability.

1.2. Industries That Use Fusion 360

- Product Design: Creating consumer products, from gadgets to furniture.

- Mechanical Engineering: Designing mechanical components and systems.

- Manufacturing: Preparing designs for manufacturing using CAM tools.

- Architecture: Conceptual design and visualization.

- Hobbyists and Makers: Designing and creating personal projects.

1.3. Why Learn Fusion 360?

- Versatility: Combines CAD, CAM, and CAE in one platform.

- Accessibility: Cloud-based, allowing access from anywhere.

- Cost-Effective: Offers a free version for hobbyists and startups.

- Industry Standard: Widely used in various industries, enhancing career prospects.

- Community Support: Large online community for learning and troubleshooting.

2. Factors Influencing Learning Time

The amount of time it takes to learn Fusion 360 can vary widely based on several factors. Understanding these can help you set realistic expectations and tailor your learning approach.

2.1. Prior Experience

- No Prior CAD Experience: Individuals with no prior experience in CAD or 3D modeling may take longer to grasp the fundamental concepts.

- Experience with Other CAD Software: Those familiar with other CAD programs like SolidWorks or AutoCAD may find the transition smoother due to overlapping principles and workflows.

2.2. Learning Style

- Visual Learners: May benefit from video tutorials and visual aids.

- Hands-On Learners: Prefer practicing with projects and real-world examples.

- Theoretical Learners: May prefer reading documentation and understanding the underlying principles.

2.3. Time Commitment

- Full-Time Learners: Devoting several hours a day to learning can accelerate the process.

- Part-Time Learners: Learning in shorter sessions may extend the timeline.

2.4. Learning Resources

- Quality of Resources: Access to high-quality tutorials, courses, and documentation can significantly impact learning speed.

- Availability of Support: Having access to forums, communities, and mentors can help resolve issues quickly.

2.5. Project Complexity

- Simple Projects: Starting with basic shapes and models can provide a solid foundation.

- Complex Projects: Tackling intricate designs and assemblies requires a deeper understanding and more practice.

3. Estimating the Learning Timeline

Given the various factors, here’s a general estimate of how long it might take to learn Fusion 360 at different proficiency levels:

3.1. Basic Proficiency (1-2 Weeks)

- What You’ll Learn:

- Navigating the Fusion 360 interface.

- Creating basic 2D sketches.

- Extruding, revolving, and lofting shapes.

- Basic assembly techniques.

- Simple part design.

- Daily Commitment: 2-3 hours.

- Expected Outcome: Ability to create simple models and assemblies.

- Example Project: Designing a simple box or a basic mechanical component.

3.2. Intermediate Proficiency (2-6 Months)

- What You’ll Learn:

- Advanced sketching techniques.

- Using constraints and parameters effectively.

- Creating complex 3D models.

- Working with surfaces.

- Performing basic simulations.

- Advanced assembly techniques.

- Basic CAM operations.

- Daily Commitment: 1-2 hours.

- Expected Outcome: Ability to design and simulate moderately complex parts and assemblies.

- Example Project: Designing a small machine part or a more intricate consumer product.

3.3. Advanced Proficiency (6+ Months)

- What You’ll Learn:

- Advanced CAM operations (toolpath strategies, post-processing).

- Complex simulations (stress analysis, thermal analysis).

- Generative design.

- API scripting and automation.

- Advanced surface modeling.

- Daily Commitment: Ongoing learning and practice.

- Expected Outcome: Ability to handle complex projects, optimize designs for manufacturing, and automate tasks.

- Example Project: Designing a complex mechanical system or optimizing a product for mass production.

4. Step-by-Step Learning Guide

To effectively learn Fusion 360, follow a structured approach that builds your skills gradually.

4.1. Step 1: Start with the Basics

- Familiarize Yourself with the Interface:

- Explore the different workspaces (Design, CAM, Simulation).

- Understand the menu structure and toolbars.

- Customize the interface to suit your workflow.

- Learn Basic Sketching:

- Master the basic sketching tools (lines, rectangles, circles, arcs).

- Understand constraints (geometric and dimensional).

- Practice creating simple 2D sketches.

- Create Basic 3D Models:

- Use the extrude, revolve, and loft commands.

- Learn to apply fillets, chamfers, and drafts.

- Practice creating simple 3D parts.

4.2. Step 2: Intermediate Techniques

- Advanced Sketching:

- Learn to use splines and conic curves.

- Understand and use sketch patterns.

- Practice creating complex sketches.

- Parametric Modeling:

- Use parameters to control your designs.

- Create design tables for variations.

- Practice creating parametric models.

- Assembly Techniques:

- Learn to create joints and constraints.

- Understand motion studies.

- Practice creating assemblies.

4.3. Step 3: Advanced Concepts

- CAM Operations:

- Learn about different machining operations (milling, turning).

- Understand toolpath strategies.

- Practice creating CAM setups and generating G-code.

- Simulation:

- Learn to perform stress analysis.

- Understand thermal analysis.

- Practice simulating your designs.

- Generative Design:

- Learn to set up generative design studies.

- Understand different manufacturing methods.

- Practice optimizing designs using generative design.

5. Essential Learning Resources

Accessing the right resources is crucial for efficient learning. Here are some of the best resources for learning Fusion 360:

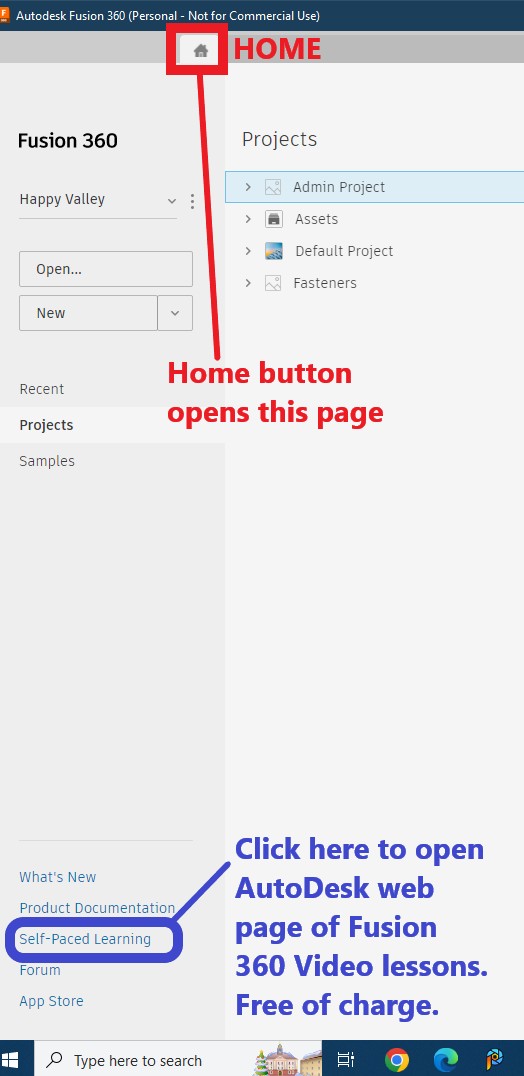

5.1. Official Autodesk Resources

- Autodesk Knowledge Network: A comprehensive resource for documentation, tutorials, and troubleshooting.

- Autodesk Fusion 360 Learning Page: Offers self-paced learning modules covering various topics.

- Autodesk Design Academy: Provides courses and learning paths for different skill levels.

Autodesk Fusion 360 Lessons

Autodesk Fusion 360 Lessons

5.2. Online Courses

- Coursera: Offers courses on Fusion 360 taught by experts from universities and industry.

- Udemy: Provides a wide range of Fusion 360 courses for different skill levels.

- LinkedIn Learning: Offers video tutorials and courses on various Fusion 360 topics.

5.3. YouTube Channels

- Autodesk Fusion 360: The official YouTube channel for Fusion 360, offering tutorials and updates.

- Product Design Online: Offers practical tutorials and tips for Fusion 360.

- Lars Christensen: Provides in-depth tutorials and insights into Fusion 360.

5.4. Forums and Communities

- Autodesk Fusion 360 Forum: A great place to ask questions and get help from other users.

- Reddit (r/Fusion360): A community where users share tips, projects, and troubleshooting advice.

5.5. Books

- “Fusion 360 for Makers” by Lydia Sloan Cline: A practical guide for hobbyists and makers.

- “Parametric Modeling with Autodesk Fusion 360” by Randy H. Shih: A comprehensive guide to parametric modeling.

6. Tips to Accelerate Your Learning

To make the most of your learning journey, consider these tips:

6.1. Set Clear Goals

- Define Your Objectives: Determine what you want to achieve with Fusion 360.

- Break Down Goals: Divide your learning into smaller, manageable steps.

- Track Your Progress: Monitor your progress and celebrate milestones.

6.2. Practice Regularly

- Consistent Practice: Dedicate time each day or week to practice.

- Real-World Projects: Work on projects that interest you.

- Challenge Yourself: Gradually increase the complexity of your projects.

6.3. Use Keyboard Shortcuts

- Learn Shortcuts: Familiarize yourself with common keyboard shortcuts.

- Customize Shortcuts: Adjust shortcuts to match your workflow.

- Increase Efficiency: Using shortcuts can significantly speed up your design process.

6.4. Join Online Communities

- Engage with Others: Participate in forums and communities.

- Ask Questions: Don’t hesitate to ask for help when you’re stuck.

- Share Your Knowledge: Help others by sharing your insights and solutions.

6.5. Stay Updated

- Follow Updates: Keep up with the latest features and updates in Fusion 360.

- Continuous Learning: Stay curious and continue learning new techniques.

7. Common Challenges and How to Overcome Them

Learning Fusion 360 can present several challenges. Recognizing these obstacles and having strategies to overcome them is essential for successful learning.

7.1. Overwhelming Interface

Challenge: The vast array of tools and options in Fusion 360 can feel overwhelming for beginners.

Solution:

- Start with basic tutorials that focus on essential tools.

- Customize the interface to display only the tools you need.

- Gradually explore additional features as you become more comfortable.

7.2. Understanding Constraints

Challenge: Properly applying constraints in sketches is crucial for parametric modeling but can be confusing.

Solution:

- Watch tutorials specifically on constraints and geometric relationships.

- Practice applying different types of constraints in simple sketches.

- Use the “Show All Constraints” feature to visualize constraints in your sketches.

7.3. Dealing with Errors

Challenge: Encountering errors and unexpected behavior can be frustrating.

Solution:

- Read error messages carefully and try to understand the cause.

- Search online forums and communities for solutions.

- Break down complex operations into smaller steps to identify the source of the error.

7.4. Mastering CAM Operations

Challenge: Learning CAM operations requires understanding machining principles and toolpath strategies.

Solution:

- Take courses or watch tutorials specifically on CAM operations in Fusion 360.

- Start with simple machining operations and gradually move to more complex ones.

- Simulate toolpaths to identify and correct potential issues before machining.

7.5. Keeping Up with Updates

Challenge: Fusion 360 is frequently updated with new features and improvements.

Solution:

- Follow the Autodesk Fusion 360 blog and social media channels for update announcements.

- Set aside time to explore new features and incorporate them into your workflow.

- Participate in webinars and online events to learn about the latest updates.

8. The Future of Fusion 360 and CAD/CAM Technology

As technology advances, Fusion 360 and the broader CAD/CAM landscape continue to evolve. Staying informed about these trends can help you prepare for future opportunities and challenges.

8.1. Integration of AI and Machine Learning

AI and machine learning are increasingly being integrated into CAD/CAM software to automate tasks, optimize designs, and improve manufacturing processes. According to a report by Grand View Research, the AI in CAD market is expected to grow significantly in the coming years due to the increasing demand for automation and optimization in design and manufacturing.

8.2. Cloud-Based Collaboration

Cloud-based platforms like Fusion 360 are becoming the standard for collaboration among designers, engineers, and manufacturers. Cloud collaboration tools enable real-time sharing of designs, feedback, and project data, improving efficiency and reducing errors.

8.3. Additive Manufacturing (3D Printing)

Fusion 360 is increasingly used in conjunction with additive manufacturing technologies. The software allows designers to create complex geometries optimized for 3D printing, and it supports various 3D printing processes.

8.4. Generative Design

Generative design is a rapidly growing field that uses algorithms to automatically generate design options based on specified constraints and objectives. Fusion 360 includes generative design capabilities, allowing users to explore a wide range of design possibilities and optimize designs for performance and manufacturability.

8.5. Augmented and Virtual Reality

Augmented reality (AR) and virtual reality (VR) are being used to visualize and interact with CAD models in new ways. AR and VR technologies allow designers and engineers to experience their designs in a realistic environment, improving design review and collaboration.

9. Case Studies: Real-World Applications of Fusion 360

Examining real-world applications of Fusion 360 can provide inspiration and demonstrate the software’s versatility and impact.

9.1. Designing Custom Prosthetics

Fusion 360 is used to design custom prosthetics tailored to individual patients. The software’s modeling tools allow designers to create prosthetics that fit comfortably and function effectively.

9.2. Developing Innovative Consumer Products

Many companies use Fusion 360 to develop innovative consumer products, from electronics to home goods. The software’s integrated CAD, CAM, and CAE tools streamline the design and manufacturing process, allowing companies to bring products to market faster.

9.3. Creating Custom Furniture

Furniture designers use Fusion 360 to create custom furniture pieces that are both functional and aesthetically pleasing. The software’s parametric modeling capabilities allow designers to easily adjust designs to meet specific requirements.

9.4. Manufacturing Precision Components

Manufacturers use Fusion 360 to create precision components for aerospace, automotive, and medical industries. The software’s advanced CAM tools allow manufacturers to optimize machining operations and produce high-quality parts with tight tolerances.

9.5. Robotics and Automation

Fusion 360 is used to design robots and automated systems for various applications, from manufacturing to healthcare. The software’s simulation tools allow designers to test and optimize robot designs before physical prototypes are built.

10. Job Opportunities and Career Paths

Mastering Fusion 360 can open up a variety of job opportunities and career paths in design, engineering, and manufacturing.

10.1. CAD Designer

CAD designers use Fusion 360 to create 2D and 3D models for various products and components. They work closely with engineers and manufacturers to ensure that designs meet functional and aesthetic requirements. According to the Bureau of Labor Statistics, the median annual wage for CAD drafters was $60,360 in May 2020.

10.2. Mechanical Engineer

Mechanical engineers use Fusion 360 to design and analyze mechanical systems and components. They work on projects ranging from consumer products to industrial equipment. The median annual wage for mechanical engineers was $90,160 in May 2020.

10.3. Manufacturing Engineer

Manufacturing engineers use Fusion 360 to plan and optimize manufacturing processes. They work to improve efficiency, reduce costs, and ensure product quality. The median annual wage for manufacturing engineers was $88,950 in May 2020.

10.4. Product Designer

Product designers use Fusion 360 to create and refine product concepts. They work on projects ranging from consumer electronics to furniture. The median annual wage for industrial designers was $75,930 in May 2020.

10.5. CNC Programmer

CNC programmers use Fusion 360 to create toolpaths for CNC machines. They work closely with machinists to produce parts and components. The median annual wage for CNC programmers was $53,470 in May 2020.

11. Optimizing Your Fusion 360 Workflow

Efficiency is key when working with Fusion 360. Optimizing your workflow can save time and reduce frustration.

11.1. Customize Your Workspace

- Arrange Tools: Place frequently used tools in easily accessible locations.

- Create Custom Toolbars: Add custom toolbars for specific tasks.

- Use Keyboard Shortcuts: Learn and customize keyboard shortcuts to speed up your workflow.

11.2. Use Templates

- Create Templates: Create templates for common projects to save time.

- Include Standard Settings: Include standard settings, such as units and materials, in your templates.

- Share Templates: Share templates with your team to ensure consistency.

11.3. Organize Your Files

- Use Folders: Create folders to organize your files and projects.

- Name Files Clearly: Use descriptive names for your files to make them easy to find.

- Version Control: Use version control to track changes and prevent data loss.

11.4. Leverage Cloud Collaboration

- Share Designs: Share designs with your team using Fusion 360’s cloud collaboration features.

- Use Comments: Use comments to provide feedback and track changes.

- Collaborate in Real-Time: Collaborate in real-time with your team to improve efficiency.

11.5. Automate Repetitive Tasks

- Use Scripts: Use scripts to automate repetitive tasks.

- Create Macros: Create macros for common operations.

- Leverage the API: Use the Fusion 360 API to integrate with other systems.

12. The Importance of Continuous Practice

Learning Fusion 360 is an ongoing process. Continuous practice is essential for maintaining and improving your skills.

12.1. Stay Engaged

- Work on Projects: Work on projects that interest you to stay engaged.

- Challenge Yourself: Continuously challenge yourself with new and complex projects.

- Set Goals: Set goals to motivate yourself and track your progress.

12.2. Seek Feedback

- Share Your Work: Share your work with others and ask for feedback.

- Be Open to Criticism: Be open to criticism and use it to improve your skills.

- Learn from Others: Learn from the experiences of others.

12.3. Stay Updated

- Follow Updates: Stay up-to-date with the latest features and updates in Fusion 360.

- Read Blogs: Read blogs and articles about Fusion 360 to learn new tips and tricks.

- Attend Webinars: Attend webinars and online events to learn from experts.

12.4. Teach Others

- Share Your Knowledge: Share your knowledge with others by teaching them Fusion 360.

- Create Tutorials: Create tutorials and guides to help others learn Fusion 360.

- Mentor Others: Mentor others and help them improve their skills.

13. Fusion 360 for Education and Training

Fusion 360 is widely used in education and training programs to teach students and professionals about CAD, CAM, and CAE.

13.1. Educational Institutions

- Universities: Many universities use Fusion 360 in engineering and design courses.

- Vocational Schools: Vocational schools use Fusion 360 to train students for careers in manufacturing and design.

- High Schools: High schools use Fusion 360 to introduce students to CAD and engineering concepts.

13.2. Training Programs

- Online Courses: Online courses offer flexible and convenient ways to learn Fusion 360.

- Workshops: Workshops provide hands-on training and personalized instruction.

- Corporate Training: Corporate training programs help employees develop their Fusion 360 skills.

13.3. Benefits of Using Fusion 360 in Education

- Accessibility: Fusion 360 is cloud-based and accessible from anywhere.

- Cost-Effective: Fusion 360 offers a free version for students and educators.

- Industry Standard: Fusion 360 is widely used in industry, making it a valuable skill for students to learn.

14. Maximizing the Value of Fusion 360 with LEARNS.EDU.VN

At LEARNS.EDU.VN, we are dedicated to helping you maximize the value of Fusion 360. Whether you’re looking to enhance your design skills, explore creative projects, or master 3D modeling, we offer resources and guidance to support your learning journey.

14.1. Comprehensive Tutorials

We provide detailed, easy-to-understand tutorials covering a wide range of Fusion 360 topics. From basic sketching to advanced CAM operations, our tutorials are designed to help you build a solid foundation and advance your skills.

14.2. Expert Guidance

Our team of experienced instructors and industry professionals are here to provide expert guidance and support. Whether you have questions about specific features or need help troubleshooting a project, we’re here to help.

14.3. Hands-On Projects

We offer a variety of hands-on projects that allow you to apply your knowledge and gain practical experience with Fusion 360. Our projects are designed to be engaging and challenging, helping you develop your skills and build your portfolio.

14.4. Community Support

Join our online community to connect with other Fusion 360 users, share your work, and get feedback. Our community is a great place to ask questions, share tips, and learn from others.

14.5. Continuous Learning Resources

We continuously update our resources to provide you with the latest information and techniques. Stay informed about new features, updates, and best practices to stay ahead in your Fusion 360 journey.

15. Frequently Asked Questions (FAQ)

15.1. Is Fusion 360 free?

Yes, Fusion 360 offers a free version for personal, non-commercial use. It also has subscription options for professional use with more advanced features.

15.2. Can Fusion 360 be used for 3D printing?

Yes, Fusion 360 is excellent for designing models for 3D printing. It supports various export formats compatible with 3D printers.

15.3. What are the system requirements for Fusion 360?

Fusion 360 requires a 64-bit processor, 4GB of RAM (8GB recommended), and a graphics card with at least 512MB of memory. A stable internet connection is also necessary.

15.4. How does Fusion 360 compare to other CAD software?

Fusion 360 stands out due to its integrated CAD/CAM/CAE capabilities, cloud-based accessibility, and relatively low cost compared to other professional CAD software.

15.5. What is the best way to learn Fusion 360?

The best way to learn Fusion 360 is through a combination of structured courses, hands-on practice, and community engagement. Set clear goals, practice regularly, and seek feedback.

15.6. Can I use Fusion 360 on a Mac?

Yes, Fusion 360 is compatible with both Windows and macOS operating systems.

15.7. What file formats does Fusion 360 support?

Fusion 360 supports a wide range of file formats, including .DWG, .DXF, .STL, .OBJ, .IGES, and .STEP.

15.8. How do I update Fusion 360?

Fusion 360 automatically updates when a new version is available. You may need to restart the software to apply the updates.

15.9. What is parametric modeling in Fusion 360?

Parametric modeling is a design approach that uses parameters to control the dimensions and relationships of a model. This allows you to easily modify and update your designs by changing parameter values.

15.10. How do I get support for Fusion 360?

You can get support for Fusion 360 through the Autodesk Knowledge Network, online forums, and by contacting Autodesk support directly.

Learning Fusion 360 is a rewarding journey that can open doors to numerous opportunities in design, engineering, and manufacturing. By understanding the factors that influence learning time, following a structured approach, and utilizing the right resources, you can become proficient in Fusion 360 and achieve your goals.

Ready to take your Fusion 360 skills to the next level? Visit LEARNS.EDU.VN today to explore our comprehensive tutorials, expert guidance, and hands-on projects. Whether you’re a beginner or an experienced user, we have the resources you need to succeed. Start your journey with us and unlock the full potential of Fusion 360. Contact us at 123 Education Way, Learnville, CA 90210, United States. Whatsapp: +1 555-555-1212. Website: learns.edu.vn.