Are you eager to learn CNC machining and unlock the potential to create intricate and precise parts? This comprehensive guide from LEARNS.EDU.VN will walk you through the essential steps, from understanding the basics to mastering advanced techniques. Discover how to transform your passion into a valuable skill, opening doors to exciting career opportunities in manufacturing, engineering, and beyond. With the right approach and resources, CNC machining can become an invaluable asset in your pursuit of technological expertise, blending computer-aided design (CAD) and computer-aided manufacturing (CAM) for optimal results.

1. Understanding the Fundamentals of CNC Machining

CNC (Computer Numerical Control) machining is a manufacturing process where pre-programmed computer software dictates the movement of factory tools and machinery. This technology allows for automated, precise, and repeatable production of parts from various materials like metal, plastic, wood, and composites. According to a study by Grand View Research, the CNC machine market is expected to reach $121.40 billion by 2025, underscoring its growing importance in modern manufacturing.

1.1. What is CNC Machining?

CNC machining uses digital instructions to control machine tools, enabling the creation of complex parts with high precision. Unlike manual machining, CNC offers automation, reducing human error and increasing productivity. The machine reads instructions from a computer program (G-code) to move cutting tools along multiple axes, shaping the raw material into the desired form.

1.2. Key Components of a CNC Machine

A CNC machine typically consists of several key components, including:

- Control Unit: The brain of the machine, interpreting the G-code and controlling the movements of the machine tools.

- Drive System: Motors and drives that move the cutting tools along the X, Y, and Z axes.

- Machine Structure: The frame and base of the machine, providing stability and support during the machining process.

- Cutting Tools: Various tools used to remove material, such as drills, mills, and lathes.

- Workholding Devices: Mechanisms to securely hold the workpiece in place during machining.

1.3. Types of CNC Machines

CNC machines come in various forms, each designed for specific applications:

| Machine Type | Description | Common Uses |

|---|---|---|

| CNC Milling Machines | Use rotary cutters to remove material from a workpiece, creating flat and 3D shapes. | Manufacturing molds, dies, and complex parts with intricate details. |

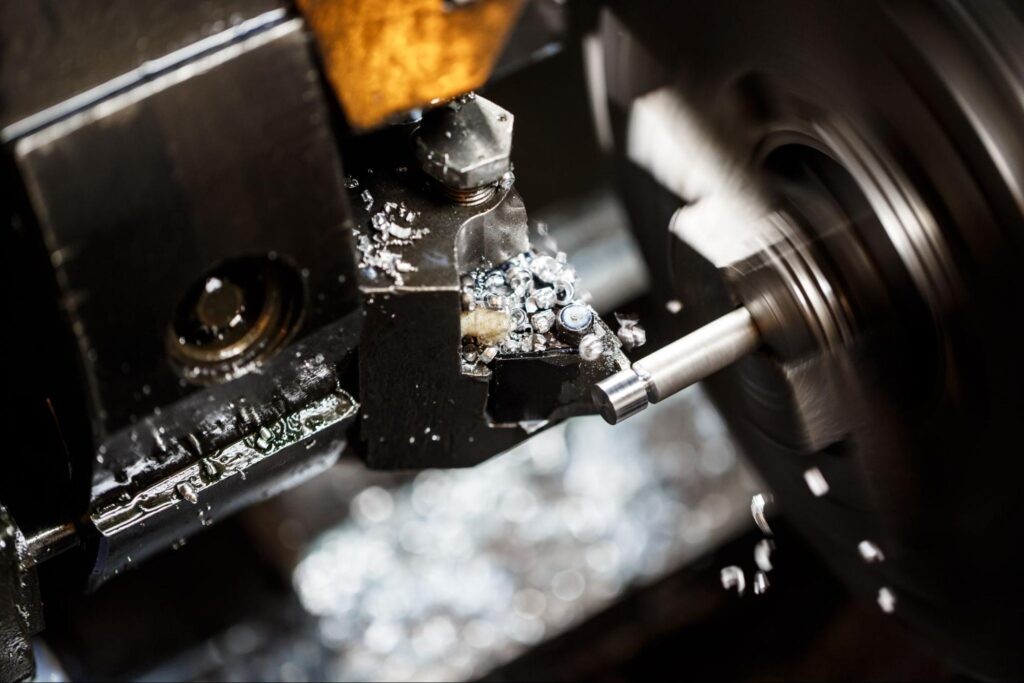

| CNC Lathes | Rotate the workpiece while feeding cutting tools to create cylindrical parts. | Producing shafts, spindles, and other round components. |

| CNC Routers | Similar to milling machines but designed for cutting softer materials like wood, plastic, and foam. | Creating signs, furniture, and prototypes. |

| CNC Plasma Cutters | Use a high-energy plasma arc to cut through metal and other conductive materials. | Cutting thick metal sheets in fabrication shops and industrial settings. |

| CNC Laser Cutters | Utilize a focused laser beam to cut or engrave materials with high precision. | Manufacturing intricate parts from metal, plastic, and wood. |

| CNC Waterjet Cutters | Employ a high-pressure stream of water mixed with abrasive particles to cut through a variety of materials. | Cutting materials that are sensitive to heat, such as stone, glass, and composites. |

| CNC Electrical Discharge Machines (EDM) | Remove material by using electrical discharges (sparks). | Manufacturing of dies, molds, and components with complex geometries and tight tolerances. |

1.4. Advantages of CNC Machining

CNC machining offers several advantages over traditional machining methods:

- Precision: CNC machines can produce parts with extremely tight tolerances, ensuring accuracy and consistency.

- Automation: CNC automates the machining process, reducing the need for manual intervention and increasing productivity.

- Repeatability: CNC machines can replicate parts with consistent quality, making them ideal for mass production.

- Complexity: CNC can create complex geometries and intricate designs that would be difficult or impossible to achieve manually.

- Efficiency: CNC machines operate at high speeds and can run continuously, maximizing throughput.

1.5. Disadvantages of CNC Machining

Despite its advantages, CNC machining also has some drawbacks:

- High Initial Cost: CNC machines can be expensive to purchase and maintain.

- Programming Complexity: Creating CNC programs requires specialized knowledge and skills.

- Setup Time: Setting up a CNC machine for a new job can be time-consuming.

- Maintenance: CNC machines require regular maintenance to ensure optimal performance.

- Skill Requirements: Operating and troubleshooting CNC machines require trained personnel.

2. Mastering CAD/CAM Software

CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software are essential tools for CNC machining. CAD software is used to create the digital designs of parts, while CAM software translates these designs into CNC machine instructions.

2.1. Introduction to CAD Software

CAD software allows designers to create 2D and 3D models of parts. These models serve as the foundation for the CNC machining process. Popular CAD software includes AutoCAD, SolidWorks, and Fusion 360. According to a report by Research and Markets, the CAD software market is projected to reach $11.21 billion by 2025, highlighting its critical role in modern design and manufacturing.

2.1.1. Key Features of CAD Software

- Parametric Modeling: Allows designers to create models with adjustable parameters, making it easy to modify designs.

- Assembly Modeling: Enables designers to assemble multiple parts into a complete product.

- Simulation: Allows designers to simulate the performance of parts and assemblies.

- Drafting: Provides tools for creating detailed 2D drawings.

- Data Management: Helps manage and organize design data.

2.1.2. Popular CAD Software Options

| Software | Description | Pros | Cons |

|---|---|---|---|

| AutoCAD | A versatile 2D and 3D CAD software used in architecture, engineering, and manufacturing. | Widely used, extensive features, large user community. | Can be expensive, steep learning curve for beginners. |

| SolidWorks | A 3D CAD software specifically designed for mechanical and electrical design, simulation, and product data management. | User-friendly interface, powerful simulation tools, integrated data management. | Can be costly, requires high-performance hardware. |

| Fusion 360 | A cloud-based CAD/CAM platform for product design, engineering, and manufacturing. | Affordable, cloud-based collaboration, integrated CAD/CAM capabilities. | Requires internet connection, limited offline functionality. |

| Creo | 3D CAD modeling software used in product design and manufacturing, offering advanced simulation and analysis tools. | Robust feature set, powerful simulation capabilities, suitable for complex designs. | High cost, complex interface, steep learning curve. |

| FreeCAD | An open-source 3D CAD modeler, making it accessible to hobbyists and students. | Free to use, open-source, customizable. | Limited features compared to commercial software, smaller user community. |

2.1.3. Tips for Learning CAD Software

- Start with the Basics: Focus on learning the fundamental concepts and tools of the software.

- Practice Regularly: Consistent practice is essential for developing proficiency.

- Follow Tutorials: Utilize online tutorials and training resources to learn specific techniques.

- Join Online Communities: Participate in forums and online communities to ask questions and share knowledge.

- Work on Projects: Apply your skills by working on real-world projects.

2.2. Introduction to CAM Software

CAM software translates CAD designs into CNC machine code (G-code). It optimizes toolpaths, simulates machining operations, and generates the necessary instructions for the CNC machine. Popular CAM software includes Mastercam, SolidCAM, and GibbsCAM.

2.2.1. Key Functions of CAM Software

- Toolpath Generation: Creates optimized toolpaths for cutting operations.

- Simulation: Simulates the machining process to detect potential errors and collisions.

- G-Code Generation: Generates the CNC machine code (G-code) required to execute the machining operations.

- Post-Processing: Converts the CAM output into a machine-specific format.

- Material Removal Simulation: Visualizes the material removal process to ensure accuracy.

2.2.2. Common CAM Software Programs

| Software | Description | Pros | Cons |

|---|---|---|---|

| Mastercam | Widely used, versatile CAM software with modules for milling, turning, wire EDM, and more. | Extensive features, broad compatibility, large user community, versatile modules for various machining processes. | Can be expensive, requires significant training. |

| SolidCAM | An integrated CAM solution for SolidWorks, providing seamless integration and advanced machining capabilities. | Seamless integration with SolidWorks, user-friendly interface, efficient toolpath generation. | Limited to SolidWorks users, can be costly. |

| GibbsCAM | A comprehensive CAM software with 2D and 3D milling, turning, and multi-task machining capabilities, suitable for complex parts. | Comprehensive features, user-friendly interface, powerful machining capabilities. | Can be expensive, requires training. |

| CATIA | A comprehensive CAD/CAM/CAE software suite primarily used in aerospace and automotive industries, offering advanced simulation and analysis tools. | Advanced simulation and analysis tools, suitable for complex designs, industry-standard in aerospace and automotive. | High cost, complex interface, steep learning curve. |

| Fusion 360 | A cloud-based CAD/CAM platform for product design, engineering, and manufacturing, providing integrated CAD and CAM capabilities. | Affordable, cloud-based collaboration, integrated CAD/CAM capabilities, user-friendly interface. | Requires internet connection, limited offline functionality, less advanced features compared to dedicated CAM software. |

2.2.3. Tips for Learning CAM Software

- Understand G-Code: Familiarize yourself with the basics of G-code programming.

- Start with Simple Projects: Begin with simple machining operations and gradually increase complexity.

- Use Simulation Tools: Take advantage of the simulation capabilities to verify toolpaths and identify potential issues.

- Optimize Toolpaths: Learn how to optimize toolpaths to reduce machining time and improve surface finish.

- Attend Training Courses: Consider attending formal training courses to gain in-depth knowledge of the software.

2.3. Integrating CAD and CAM

Integrating CAD and CAM software streamlines the CNC machining process. By seamlessly transferring designs from CAD to CAM, you can reduce errors, improve efficiency, and optimize machining operations.

- Direct File Transfer: Transfer CAD files directly into the CAM software without the need for intermediate file formats.

- Associative Modeling: Changes made to the CAD model are automatically updated in the CAM software.

- Integrated Workflows: Streamline the design and manufacturing process by integrating CAD and CAM workflows.

- Data Management: Manage design and manufacturing data in a centralized system.

- Collaboration: Facilitate collaboration between designers and machinists.

3. Diving into CNC Programming

CNC programming involves writing the instructions that control the CNC machine. These instructions, known as G-code, specify the movements, speeds, and operations of the machine tools.

3.1. Understanding G-Code

G-code is a programming language used to control CNC machines. It consists of a series of commands that instruct the machine to perform specific actions, such as moving the cutting tool, changing speed, and turning coolant on or off.

3.1.1. Key G-Code Commands

- G00: Rapid traverse (non-cutting move).

- G01: Linear interpolation (cutting move).

- G02: Circular interpolation clockwise.

- G03: Circular interpolation counterclockwise.

- G20: Inch units.

- G21: Millimeter units.

- G90: Absolute programming.

- G91: Incremental programming.

- M03: Spindle start clockwise.

- M04: Spindle start counterclockwise.

- M05: Spindle stop.

- M08: Coolant on.

- M09: Coolant off.

- M30: Program end.

3.1.2. Structure of a G-Code Program

A G-code program typically consists of a header, a body, and a footer. The header contains information about the program, such as the machine type and units. The body contains the actual machining instructions. The footer signals the end of the program.

%

O1234 (Program Number)

N10 G20 (Inch Units)

N20 G90 (Absolute Programming)

N30 G00 X0 Y0 (Rapid Traverse to X0 Y0)

N40 G01 Z-0.25 F5.0 (Linear Interpolation to Z-0.25 at Feed Rate 5.0)

N50 G00 Z1.0 (Rapid Traverse to Z1.0)

N60 M30 (Program End)

%3.1.3. Resources for Learning G-Code

- Online Tutorials: Websites like CNC Cookbook and YouTube offer comprehensive G-code tutorials.

- Textbooks: Numerous textbooks cover CNC programming and G-code in detail.

- Training Courses: Vocational schools and technical colleges offer CNC programming courses.

- Software Documentation: CAM software often includes documentation on G-code programming.

3.2. Understanding M-Code

M-code is another set of commands used in CNC programming to control miscellaneous machine functions. These functions include starting and stopping the spindle, turning coolant on and off, and changing tools.

3.2.1. Common M-Code Commands

- M00: Program stop.

- M01: Optional program stop.

- M03: Spindle start clockwise.

- M04: Spindle start counterclockwise.

- M05: Spindle stop.

- M06: Tool change.

- M08: Coolant on.

- M09: Coolant off.

- M30: Program end.

3.2.2. Using M-Code in CNC Programs

M-code commands are inserted into the G-code program to control various machine functions. For example, the command M03 is used to start the spindle, while M05 is used to stop it.

N10 G00 X0 Y0

N20 M03 S1000 (Spindle Start Clockwise at 1000 RPM)

N30 G01 Z-0.25 F5.0

N40 M05 (Spindle Stop)

N50 M303.3. Manual Programming vs. CAM Programming

CNC programs can be created manually by writing G-code or automatically using CAM software. Manual programming requires a thorough understanding of G-code and machine operations, while CAM programming automates the process of generating G-code from CAD designs.

3.3.1. Manual Programming

- Pros: Provides a deep understanding of G-code and machine operations, allows for precise control over machining parameters.

- Cons: Time-consuming, requires specialized knowledge, prone to errors.

3.3.2. CAM Programming

- Pros: Automates the programming process, reduces errors, optimizes toolpaths, supports complex geometries.

- Cons: Requires CAM software, may not always produce the most efficient code, can be expensive.

3.4. Tips for Writing Effective CNC Programs

- Plan Ahead: Before writing the program, plan the machining operations and toolpaths.

- Use Comments: Add comments to the program to explain the purpose of each section.

- Verify Toolpaths: Use simulation tools to verify toolpaths and identify potential issues.

- Optimize Code: Optimize the code to reduce machining time and improve surface finish.

- Test Thoroughly: Test the program on a non-critical part before running it on the final workpiece.

4. Setting Up Your CNC Machine

Proper setup is crucial for successful CNC machining. This involves preparing the machine, loading the tools, setting the work offsets, and calibrating the machine coordinates.

4.1. Preparing the Machine

Before starting any machining operation, ensure the CNC machine is clean and in good working condition.

- Clean the Machine: Remove any chips, coolant residue, and dust from prior use.

- Inspect Components: Check for any signs of damage or wear on the machine components.

- Lubricate Moving Parts: Lubricate the machine’s moving parts according to the manufacturer’s recommendations.

- Verify Coolant Level: Ensure the coolant level is adequate for the machining operation.

- Check Safety Devices: Verify that all safety devices, such as emergency stop buttons and interlocks, are functioning properly.

4.2. Loading and Aligning Tools

Select the appropriate cutting tools for the machining operations and load them into the machine.

- Select Cutting Tools: Choose the cutting tools based on the material being machined, the desired surface finish, and the machining parameters.

- Inspect Tools: Check the tools for any signs of damage or wear.

- Load Tools: Load the tools into the toolholders or tool changer turret, following the manufacturer’s guidelines.

- Align Tools: Ensure proper calibration and alignment using dial indicators or laser alignment.

4.3. Setting Tool Length Offsets

Measure and set the tool lengths from a reference point to ensure accurate machining.

- Measure Tool Lengths: Measure the tool lengths using a tool presetter or manual measurement.

- Set Offsets: Enter the tool length offsets into the machine’s control system.

- Verify Offsets: Verify the offsets by running a test program and checking the dimensions of the machined part.

4.4. Installing the Workpiece

Secure the workpiece in the CNC machine’s workholding device, such as a vise or chuck.

- Select Workholding Device: Choose the appropriate workholding device based on the size and shape of the workpiece.

- Secure Workpiece: Secure the workpiece in the workholding device, ensuring it is properly aligned and clamped.

- Verify Alignment: Use reference edges and faces to ensure proper alignment.

4.5. Calibrating Machine Coordinates

Set the position of the “workpiece zero” in the work coordinate system (WCS) to align the machine’s reference point for starting the machining operations.

- Establish Workpiece Zero: Define the workpiece zero point on the workpiece.

- Set Coordinates: Enter the coordinates of the workpiece zero point into the machine’s control system.

- Verify Coordinates: Verify the coordinates by running a test program and checking the position of the cutting tool.

4.6. Loading the CNC Program

Import the CNC program into the machine’s control system.

- Transfer Program: Transfer the program via USB, local area network, or floppy disk.

- Verify Program: Verify the program by reviewing the code and checking for errors.

4.7. Performing a Test Run

Before running the program on the final workpiece, perform a test run to verify the toolpaths and machining parameters.

- Reduce Feed Rate: Reduce the feed rate to slow down the machining process.

- Dry Run: Run the program without a workpiece to check for collisions and errors.

- Verify Dimensions: Machine a test part and verify the dimensions to ensure accuracy.

5. Monitoring and Troubleshooting CNC Operations

During CNC machining, it’s crucial to monitor the machine’s performance and troubleshoot any issues that may arise.

5.1. Monitoring Machine Performance

Keep a close eye on the machine’s performance to detect any signs of problems.

- Watch Cutting Tools: Observe the cutting tools through the machine’s window.

- Listen for Unusual Sounds: Listen for any unusual sounds, such as excessive vibration or grinding.

- Monitor Coolant Flow: Check the coolant flow to ensure it is adequate.

- Monitor Temperatures: Monitor the temperatures on the control screen to detect overheating.

- Check for Smoke or Burning Smell: If you see smoke or smell something burning, shut down the machine immediately.

5.2. Common CNC Machining Problems

- Tool Breakage: Cutting tools can break due to excessive force, improper setup, or worn tools.

- Vibration: Vibration can cause poor surface finish, inaccurate dimensions, and tool breakage.

- Chatter: Chatter is a form of vibration that occurs when the cutting tool oscillates rapidly.

- Overheating: Overheating can damage the cutting tool, the workpiece, and the machine.

- Inaccurate Dimensions: Inaccurate dimensions can result from improper setup, worn tools, or errors in the CNC program.

- Poor Surface Finish: Poor surface finish can be caused by vibration, chatter, or improper machining parameters.

5.3. Troubleshooting Tips

- Check the Program: Verify that the CNC program is correct and free of errors.

- Inspect the Tools: Check the cutting tools for any signs of damage or wear.

- Verify the Setup: Ensure that the machine is properly set up and calibrated.

- Adjust Machining Parameters: Adjust the machining parameters, such as speed, feed rate, and depth of cut.

- Use Vibration Dampeners: Use vibration dampeners to reduce vibration and chatter.

- Improve Coolant Flow: Increase the coolant flow to reduce heat and improve lubrication.

- Seek Expert Assistance: If you are unable to resolve the problem, seek assistance from a qualified CNC technician.

6. Selecting the Right Tooling

Choosing the right tooling is critical for achieving accurate, efficient, and high-quality CNC machining.

6.1. Types of Cutting Tools

There are various types of cutting tools, each designed for specific machining operations and materials.

- End Mills: Used for milling flat surfaces, contours, and pockets.

- Ball Nose Mills: Used for creating curved surfaces and 3D shapes.

- Drills: Used for creating holes.

- Taps: Used for creating threads.

- Reamers: Used for enlarging and finishing holes.

- Turning Tools: Used for turning operations on lathes.

6.2. Material Considerations

The material of the cutting tool should be selected based on the material being machined.

- High-Speed Steel (HSS): Suitable for machining softer materials like aluminum and plastic.

- Carbide: Suitable for machining harder materials like steel and stainless steel.

- Ceramic: Suitable for machining very hard materials like hardened steel and cast iron.

- Diamond: Suitable for machining abrasive materials like composites and ceramics.

6.3. Coating Options

Coatings can improve the performance and lifespan of cutting tools.

- Titanium Nitride (TiN): Improves hardness and wear resistance.

- Titanium Carbonitride (TiCN): Improves hardness, wear resistance, and heat resistance.

- Aluminum Titanium Nitride (AlTiN): Improves heat resistance and wear resistance.

- Diamond-Like Carbon (DLC): Reduces friction and improves surface finish.

6.4. Geometry and Design

The geometry and design of the cutting tool can significantly impact its performance.

- Number of Flutes: More flutes provide a smoother finish but reduce chip clearance.

- Helix Angle: Higher helix angles improve chip evacuation.

- Cutting Edge Angle: Affects the cutting force and surface finish.

- Relief Angle: Prevents the tool from rubbing against the workpiece.

6.5. Tool Holding Systems

Proper tool holding is essential for accurate and efficient machining.

- Collet Chucks: Provide a secure and accurate grip on the cutting tool.

- Hydraulic Chucks: Offer high clamping force and vibration damping.

- Shrink-Fit Holders: Provide a very rigid and accurate connection between the tool and the spindle.

7. Ensuring a Stable Power Supply

A stable and consistent power supply is crucial for the reliable operation of CNC machines.

7.1. Understanding Power Requirements

CNC machines typically require a 3-phase power supply to operate efficiently.

- Single-Phase Power: Common in residential and small commercial settings.

- 3-Phase Power: Provides more consistent and reliable power, required for most industrial equipment.

7.2. Rotary Phase Converters

If 3-phase power is not available, a rotary phase converter can be used to convert single-phase power to 3-phase power. According to the U.S. Department of Energy, phase converters are an effective solution for powering 3-phase equipment in locations where 3-phase power is not readily accessible.

-

Benefits of Rotary Phase Converters:

- Cost-effective alternative to installing 3-phase power.

- Provides balanced and reliable 3-phase power.

- Suitable for powering multiple machines simultaneously.

-

Considerations When Choosing a Phase Converter:

- Size the converter appropriately for the CNC machine’s power requirements.

- Choose a high-quality converter from a reputable manufacturer.

- Ensure the converter is properly installed and grounded.

7.3. Power Conditioning

Power conditioning devices can protect CNC machines from voltage fluctuations and power surges.

- Surge Suppressors: Protect against voltage spikes that can damage sensitive electronic components.

- Voltage Regulators: Maintain a consistent voltage level to ensure stable machine operation.

- Uninterruptible Power Supplies (UPS): Provide backup power in the event of a power outage.

8. Prioritizing Safety in CNC Machining

Safety should always be a top priority when working with CNC machines.

8.1. Personal Protective Equipment (PPE)

Wear appropriate PPE to protect yourself from hazards.

- Safety Glasses: Protect your eyes from flying chips and debris.

- Hearing Protection: Protect your ears from loud noises.

- Gloves: Protect your hands from sharp edges and chemicals.

- Safety Shoes: Protect your feet from falling objects.

8.2. Machine Safety Features

Familiarize yourself with the machine’s safety features.

- Emergency Stop Buttons: Quickly shut down the machine in case of an emergency.

- Interlocks: Prevent the machine from operating when safety guards are open.

- Light Curtains: Automatically shut down the machine when a laser beam is interrupted.

- Chip Guards: Prevent flying chips from causing injury.

8.3. Safe Operating Procedures

Follow safe operating procedures to minimize the risk of accidents.

- Never operate the machine without proper training.

- Keep the work area clean and organized.

- Never reach into the machine while it is running.

- Use the correct tools and equipment for the job.

- Follow the manufacturer’s instructions.

- Report any safety hazards to your supervisor.

9. Continuing Education and Resources

CNC machining is a constantly evolving field. Stay up-to-date with the latest technologies and techniques through continuing education and resources.

9.1. Online Courses and Tutorials

- Coursera: Offers courses on CNC machining, CAD/CAM, and manufacturing processes.

- Udemy: Provides a wide range of CNC machining tutorials and courses.

- YouTube: Features numerous channels with CNC machining tips, techniques, and demonstrations.

- LEARNS.EDU.VN: This website provides in-depth articles, tutorials, and resources for CNC machining enthusiasts and professionals alike. Discover advanced techniques, troubleshooting tips, and the latest industry trends.

9.2. Vocational Schools and Technical Colleges

- Local vocational schools and technical colleges: Offer certificate and degree programs in CNC machining and manufacturing technology.

9.3. Industry Associations

- Society of Manufacturing Engineers (SME): Provides resources, training, and networking opportunities for manufacturing professionals.

- National Tooling and Machining Association (NTMA): Represents the interests of the tooling and machining industry.

9.4. Books and Publications

- “CNC Programming Handbook” by Peter Smid: A comprehensive guide to CNC programming.

- “Machinery’s Handbook”: A classic reference book for machinists and engineers.

- “Modern Manufacturing Processes” by James G. Bralla: Covers various manufacturing processes, including CNC machining.

10. Real-World Applications of CNC Machining

CNC machining is used in a wide range of industries to manufacture a variety of products.

10.1. Aerospace Industry

CNC machining is used to produce critical components for aircraft and spacecraft, such as engine parts, structural components, and landing gear. According to a report by Deloitte, the aerospace industry relies heavily on CNC machining for its ability to produce complex, high-precision parts.

10.2. Automotive Industry

CNC machining is used to manufacture engine parts, transmission components, and other critical automotive parts. The automotive industry uses CNC machining for its ability to produce parts in high volumes with consistent quality.

10.3. Medical Industry

CNC machining is used to produce surgical instruments, medical implants, and other medical devices. The medical industry relies on CNC machining for its ability to produce parts with extremely tight tolerances and high levels of precision.

10.4. Electronics Industry

CNC machining is used to produce circuit boards, electronic enclosures, and other electronic components. The electronics industry uses CNC machining for its ability to produce small, intricate parts with high precision.

10.5. Consumer Products Industry

CNC machining is used to produce a wide range of consumer products, such as mobile phones, appliances, and sporting goods. The consumer products industry uses CNC machining for its ability to produce parts in high volumes with consistent quality and complex designs.

Conclusion:

Learning CNC machining opens doors to a world of possibilities in manufacturing, engineering, and design. With a solid understanding of the fundamentals, mastery of CAD/CAM software, and a commitment to safety, you can unlock your potential and create innovative solutions in a variety of industries. Remember, the journey of learning is continuous, so keep exploring, practicing, and staying updated with the latest advancements. For more in-depth knowledge and resources, visit LEARNS.EDU.VN, your go-to destination for educational excellence. Whether you’re aiming to enhance your skills or embark on a new career path, LEARNS.EDU.VN is here to guide you every step of the way.

Ready to take your CNC machining skills to the next level? Visit LEARNS.EDU.VN today to explore our comprehensive courses and resources. Our expert instructors and hands-on training will empower you with the knowledge and skills you need to succeed. Don’t wait – start your journey to CNC mastery with LEARNS.EDU.VN!

Contact Information:

- Address: 123 Education Way, Learnville, CA 90210, United States

- WhatsApp: +1 555-555-1212

- Website: learns.edu.vn

Frequently Asked Questions (FAQ)

1. What is CNC machining?

CNC machining is a manufacturing process in which pre-programmed computer software dictates the movement of factory tools and machinery. It’s used to create precise parts from various materials.

2. What are the key components of a CNC machine?

Key components include the control unit, drive system, machine structure, cutting tools, and workholding devices.

3. What types of CNC machines are there?

Common types include CNC milling machines, CNC lathes, CNC routers, CNC plasma cutters, CNC laser cutters, and CNC waterjet cutters.

4. What software is essential for CNC machining?

CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software are essential. CAD is used to create designs, while CAM translates these designs into CNC machine instructions.

5. What is G-code?

G-code is a programming language used to control CNC machines. It provides instructions for the machine’s movements, speeds, and operations.

6. What is M-code?

M-code is a set of commands used to control miscellaneous machine functions, such as starting and stopping the spindle and turning coolant on and off.

7. How do I set up a CNC machine properly?

Proper setup involves preparing the machine, loading and aligning tools, setting tool length offsets, installing the workpiece, and calibrating machine coordinates.

8. What should I monitor during CNC operations?

Monitor the cutting tools, listen for unusual sounds, check coolant flow, and monitor temperatures to ensure optimal performance and safety.

9. What are some common problems in CNC machining?

Common problems include tool breakage, vibration, chatter, overheating, inaccurate dimensions, and poor surface finish.

10. How can I ensure safety when using CNC machines?

Prioritize safety by wearing personal protective equipment (PPE), understanding machine safety features, and following safe operating procedures.